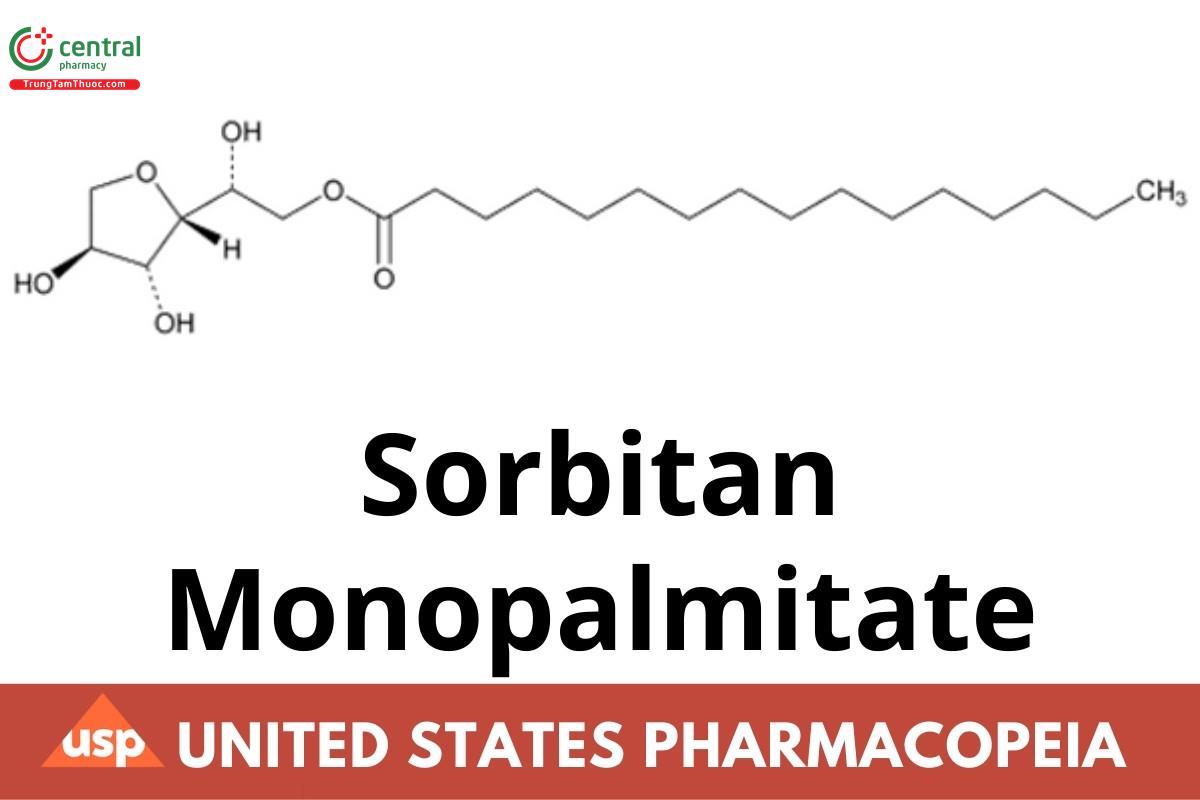

Sorbitan Monopalmitate

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

Sorbitan Monopalmitate is a partial ester of palmitic acid with Sorbitol and its mono- and dianhydrides. It yields, upon saponification, NLT 63.0% and NMT 71.0% of fatty acids, and NLT 32.0% and NMT 38.0% of polyols (w/w).

2 IDENTIFICATION

A.

Sample: Residue obtained in the Assay for Fatty Acids Acceptance criteria

FATS AND FIXED OILS, ACID VALUE 〈401〉: 210–225 on 1-g sample

FATS AND FIXED OILS, IODINE VALUE 〈401〉: NMT 4

B. THIN-LAYER CHROMATOGRAPHIC IDENTIFICATION TEST 〈201〉

Standard solution: 33 mg/mL of USP Isosorbide RS, 25 mg/mL of USP 1,4-Sorbitan RS, and 25 mg/mL of sorbitol Sample solution: 250 mg/mL of the polyols, obtained in the Assay for Polyols

Chromatographic system

(See Chromatography 〈621〉, Thin-Layer Chromatography.) Mode: TLC

Adsorbent: 0.25-mm layer of chromatographic silica gel Application volume: 2 µL

Developing solvent system: Acetone and glacial acetic acid (50:1) Spray reagent: Sulfuric acid and water (50:50)

Analysis

Samples: Standard solution and Sample solution

Apply the Standard solution and Sample solution, and allow the spots to dry. Develop the chromatogram until the solvent front has moved about three-fourths of the length of the plate. Remove the plate from the developing chamber, mark the solvent front, and allow the solvent to evaporate. Spray evenly with Spray reagent until the surface is uniformly wet (do not overspray), and immediately place the sprayed plate on a 200° hot plate in a well-ventilated hood. Char until white fumes of sulfur trioxide cease, and cool.

Acceptance criteria: The R values of the spots of the Sample solution correspond to those of the spots of the Standard solution.

3 ASSAY

3.1 FATTY ACIDS

Sample: 10 g

Analysis: Transfer the Sample to a 500-mL conical flask. Cautiously add 100 mL of alcohol and 3.0 g of potassium hydroxide. Connect a suitable condenser to the flask, reflux the mixture on a hot plate for 2 h, add 100 mL of water, and heat on a steam bath to evaporate the alcohol, adding water occasionally to replace the alcohol. Continue the evaporation until the odor of alcohol can no longer be detected, and transfer the saponification mixture, with the aid of 100 mL of hot water, to a 500-mL separator. Using extreme caution, neutralize to litmus paper with a mixture of equal volumes of sulfuric acid and water, noting the volume used, and add a 10% excess of the dilute acid. Allow the solution to cool. If salts appear, add sufficient water to produce a clear solution. Cautiously add 100 mL of solvent hexane, shake thoroughly, and withdraw the lower layer into a second 500-mL separator. Similarly extract with two more 100-mL portions of solvent hexane. Extract the combined hexane layers with 50-mL portions of water until neutral to litmus paper. Combine the extracts with the original aqueous phase to use for the Assay for Polyols. Evaporate the solvent hexane in a tared beaker on a steam bath nearly to dryness, dry under vacuum at 60° for 1 h, cool in a desiccator, and weigh the fatty acids.

Acceptance criteria: 63.0%–71.0%

3.2 POLYOLS

Sample solution: Aqueous solution retained from the Assay for Fatty Acids

Analysis: Neutralize the Sample solution with a potassium hydroxide solution (1 in 10) to a pH of 7, using a pH meter. Evaporate on a steam bath to a moist residue, extract the polyols from the salts with three 150-mL portions of dehydrated alcohol, boiling the salt residue for 3 min, and crushing it, as necessary, with the flattened end of a stirring rod during each extraction; filtering each extract while hot through a medium-porosity, sintered-glass funnel provided with a sheet of retentive filter paper on which a layer of purified siliceous earth has been superimposed; and receiving the filtrates in a 1-L suction flask. Transfer the clear alcoholic polyols solution to a tared beaker, evaporate the alcohol on a steam bath, dry under vacuum at 60° for 1 h, cool in a desiccator, and weigh the polyols.

Acceptance criteria: 32.0%–38.0% (w/w)

4 IMPURITIES

RESIDUE ON IGNITION 〈281〉: NMT 0.5%

5 SPECIFIC TESTS

WATER DETERMINATION, Method I〈921〉: NMT 1.5%

FATS AND FIXED OILS, Acid Value〈401〉: NMT 8

FATS AND FIXED OILS, Hy droxyl Value〈401〉: 275–305

FATS AND FIXED OILS, Saponification Value〈401〉: 140–150

6 ADDITIONAL REQUIREMENTS

PACKAGING AND STORAGE: Preserve in well-closed containers.

USP REFERENCE STANDARDS 〈11〉

USP Isosorbide RS

USP 1,4-Sorbitan RS C6H12O5 164.16