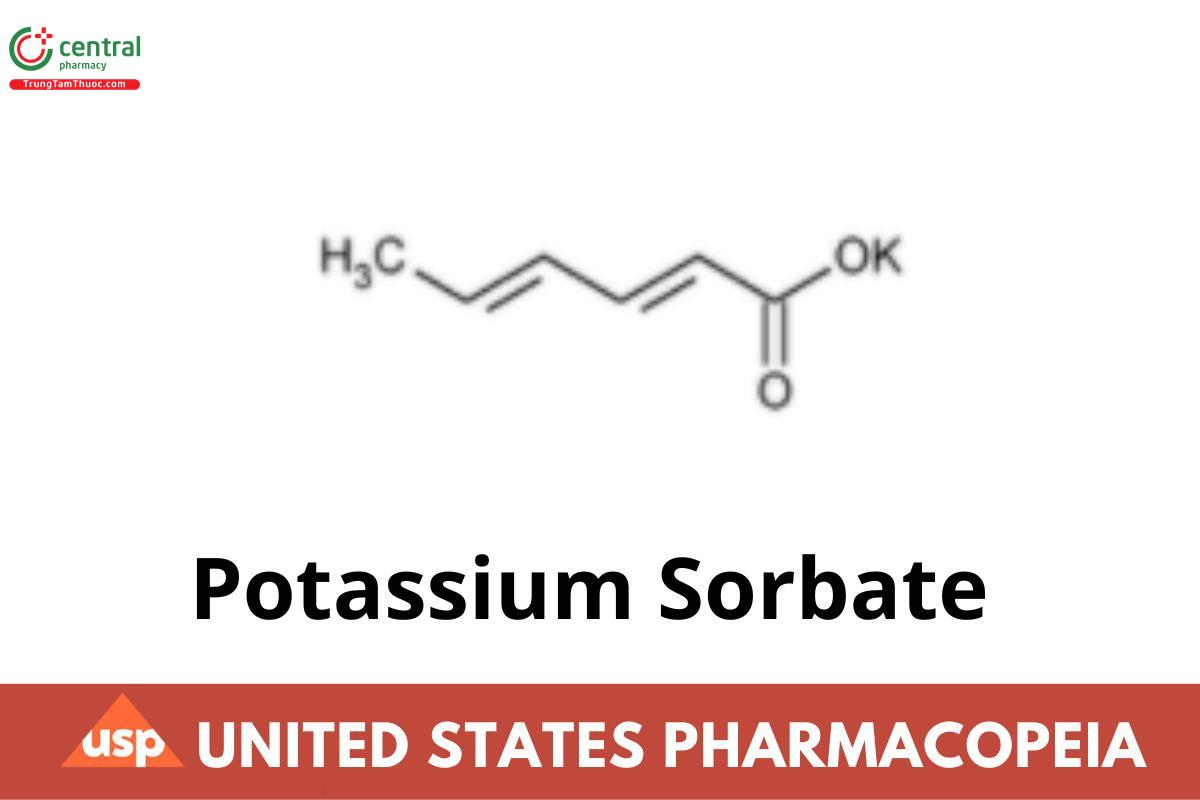

Potassium Sorbate

If you find any inaccurate information, please let us know by providing your feedback here

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

DOWNLOAD PDF HERE

1 DEFINITION

Change to read:

Potassium Sorbate contains NLT 98.0% and NMT 102.0% (NF 1-May-2020) of potassium sorbate (C6H7KO2), calculated on the dried basis.

2 IDENTIFICATION

A. Identification Tests—General 〈191〉, Chemical Identification Tests, Potassium

Sample: Dissolve 1 g of Potassium Sorbate in 10 mL of water.

Acceptance criteria: Meets the requirements

Change to read:

B. Spectroscopic Identification Tests 〈197〉, Infrared Spectroscopy: 197A or 197K (NF 1-May-2020)

3 ASSAY

Delete the following:

Procedure

Sample: 300 mg of Potassium Sorbate

Blank: 40 mL of glacial acetic acid

Titrimetric system

(See Titrimetry 〈541〉.)

Mode: Direct titration

Titrant: 0.1 N perchloric acid VS

Endpoint detection: Visual

Analysis: Dissolve the Sample in 40 mL of glacial acetic acid, warming, if necessary, to dissolve the solution. Cool to room temperature, and

add 1 drop of crystal violet TS. Titrate with Titrant to a blue-green endpoint. Perform a blank determination.

Calculate the percentage of potassium sorbate (C6H7KO2) in the Sample taken:

Result = {[(VS − VB) × N × F]/W} ×100

VS = Titrant consumed by the Sample (mL)

VB = Titrant consumed by the Blank (mL)

N = actual normality of the Titrant (mEq/mL)

F = equivalency factor, 150.2 mg/mEq

W = Sample weight (mg)

Acceptance criteria: 98.0%–101.0% on the dried basis (NF 1-May-2020)

Add the following:

Procedure 1: Content of Potassium Sorbate

Solution A: 0.1% (v/v) trifluoroacetic acid in water

Solution B: 0.1% (v/v) trifluoroacetic acid in methanol

Mobile phase: See Table 1.

Table 1

Time (min) | Solution A (%) | Solution B (%) |

| 0 | 75 | 25 |

| 17.0 | 75 | 25 |

| 18.0 | 5 | 95 |

| 23.0 | 5 | 95 |

| 23.1 | 75 | 25 |

| 30 | 75 | 25 |

Diluent: Water and methanol (1:1, v/v)

System suitability solution: Prepare 0.1 mg/mL of USP Potassium Sorbate RS in Diluent first and then treat the solution with UV irradiation to generate ∼1% degradation of potassium sorbate (based on area%).1

Standard solution: 0.1 mg/mL of USP Potassium Sorbate RS in Diluent

Sample solution: 0.1 mg/mL of Potassium Sorbate in Diluent

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 264 nm

Column: 4.6-mm × 15-cm; 3.5-μm packing L1

Column temperature: 40°

Flow rate: 1.0 mL/min

Injection volume: 10 μL

Run time: 30 min

System suitability

Samples: System suitability solution and Standard solution

[Note—The approximate relative retention times of related substances are listed in Table 2.]

Suitability requirements

Resolution: NLT 1.5 between potassium sorbate and potassium sorbate trans, cis isomer, System suitability solution

Tailing factor: NMT 2.0, determined from potassium sorbate, Standard solution

Relative standard deviation: NMT 2.0%, determined from potassium sorbate, Standard solution

Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of potassium sorbate in the sample taken:

Result = (rU/rS) × (CS/CU) × 100

rU = peak area of potassium sorbate from the Sample solution

rS = peak area of potassium sorbate from the Standard solution

CS = concentration of USP Potassium Sorbate RS in the Standard solution (mg/mL)

CU = concentration of Potassium Sorbate in the Sample solution (mg/mL)

Acceptance criteria: 98.0%–102.0% on the dried basis

Table 2

| Name | Relative Retention Time |

| Potassium sorbate cis, cis isomera | 0.83 |

| Potassium sorbate cis, trans isomerb | 0.89 |

| Potassium sorbate trans, cis isomerc | 0.92 |

| Potassium sorbate | 1.0 |

a Potassium (Z,Z)-sorbate.

b Potassium (Z,E)-sorbate.

c Potassium (E,Z)-sorbate.

[Note—Potassium sorbate cis, trans isomer and potassium sorbate trans, cis isomer might co-elute in some columns, which has no effects on assay analysis. All the four isomers are in their corresponding sorbic acid forms in the HPLC column because of the acidic mobile phase condition.] (NF 1-May-2020)

Add the following:

Procedure 2: Content of Potassium

Diluent: 1% hydrochloric acid solution

Sodium chloride solution: 0.2 g/mL of sodium chloride in Diluent

Blank solution: 4 mg/mL of sodium chloride from Sodium chloride solution in Diluent

Standard stock solution: 57.21 μg/mL of potassium chloride, previously dried at 105° for 2 h, in water. This solution contains 30 μg/mL of potassium.

Standard solutions: Transfer 2.0-, 4.0-, and 6.0-mL portions of the Standard stock solution to separate 100-mL volumetric flasks. To each flask add 2.0 mL of the Sodium chloride solution. Dilute the content of each flask with Diluent to volume and mix to obtain solutions with known concentrations of 0.6, 1.2, and 1.8 μg/mL of potassium.

Sample stock solution: 0.46 mg/mL of Potassium Sorbate in water

Sample solution: Transfer 1.0 mL of the Sample stock solution to a 100-mL volumetric flask. Add 2.0 mL of the Sodium chloride solution and dilute with Diluent to volume. The concentration of this solution is 4.6 μg/mL of Potassium Sorbate.

Instrumental conditions

(See Atomic Absorption Spectroscopy 〈852〉.)

Mode: Atomic absorption spectrophotometry

Analytical wavelength: 766.5 nm (potassium emission line)

Lamp: Potassium hollow-cathode

Flame: Air–acetylene

Standard curve

Samples: Standard solutions

Plot: Absorbance values versus their corresponding concentrations (μg/mL) of potassium. The correlation coeficient is NLT 0.995.

Analysis

Sample: Sample solution

From the Standard curve, determine the concentration of potassium in the Sample solution.

Calculate the percentage of potassium in the portion of Potassium Sorbate taken:

Result = (CS/CU) × 100

CS = concentration of potassium in the Sample solution from the Standard curve (μg/mL)

CU = concentration of Potassium Sorbate in the Sample solution (μg/mL)

Acceptance criteria: 24.5%–27.6% (NF 1-May-2020)

4 IMPURITIES

Add the following:

Limit of Aldehyde

Decolorized fuchsin solution: Dissolve 0.1 g of basic fuchsin in 60 mL of water. Add a solution containing 1 g of anhydrous sodium sulfite in 10 mL of water. Slowly and with continuous shaking add 2 mL of hydrochloric acid. Dilute with water to 100 mL. Allow to stand protected from light for at least 12 h, decolorize with activated charcoal, and filter. If the solution becomes cloudy, filter before use. If on standing the solution becomes violet, decolorize again by adding activated charcoal.

Test for sensitivity: To 1.0 mL of Decolorized fuchsin solution add 1.0 mL of water and 0.1 mL of alcohol, aldehyde-free. Add 0.2 mL of a solution containing 0.1 g/L of formaldehyde (CH O). A pale-pink color develops within 5 min.

Storage: Protected from light

Acetaldehyde standard solution: 100 μg/mL of acetaldehyde (C H O). Dissolve 1.0 g of acetaldehyde in 2-propanol and dilute with the same solvent to 100.0 mL. Dilute 5.0 mL of the solution with 2-propanol to 500.0 mL. Prepare immediately before use.

Standard solution: Add 1 mL of Decolorized fuchsin solution to a mixture of 1.5 mL of Acetaldehyde standard solution, 4 mL of 2-propanol, and 4.5 mL of water.

Sample solution: Dissolve 1.0 g of the sample in a mixture of 30 mL of water and 50 mL of 2-propanol, adjust with 1 N hydrochloric acid to a pH of 4, and dilute with water to 100 mL.

Analysis: To 10 mL of the Sample solution add 1 mL of Decolorized fuchsin solution and allow to stand for 30 min. Any color in the solution is not more intense than that in the Standard solution prepared at the same time.

Acceptance criteria: NMT 0.15%, as acetaldehyde (NF 1-May-2020)

5 SPECIFIC TESTS

Acidity or Alkalinity

Sample solution: 1.1 g of Potassium Sorbate in 20 mL of water

Analysis: Add phenolphthalein TS to the Sample solution.

Acceptance criteria: If the solution is colorless, titrate with 0.10 N sodium hydroxide to a pink color that persists for 15 s: NMT 1.1 mL of 0.10

N sodium hydroxide is required. If the solution is pink in color, titrate with 0.10 N hydrochloric acid to discharge the pink color: NMT 0.80 mL of 0.10 N hydrochloric acid is required.

Loss on Drying 〈731〉

Analysis: Dry at 105° for 3 h.

Acceptance criteria: NMT 1.0%

6 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in tight containers, protected from light, and avoid exposure to excessive heat.

Add the following:

USP Reference Standards 〈11〉

USP Potassium Sorbate RS (NF 1-May-2020)