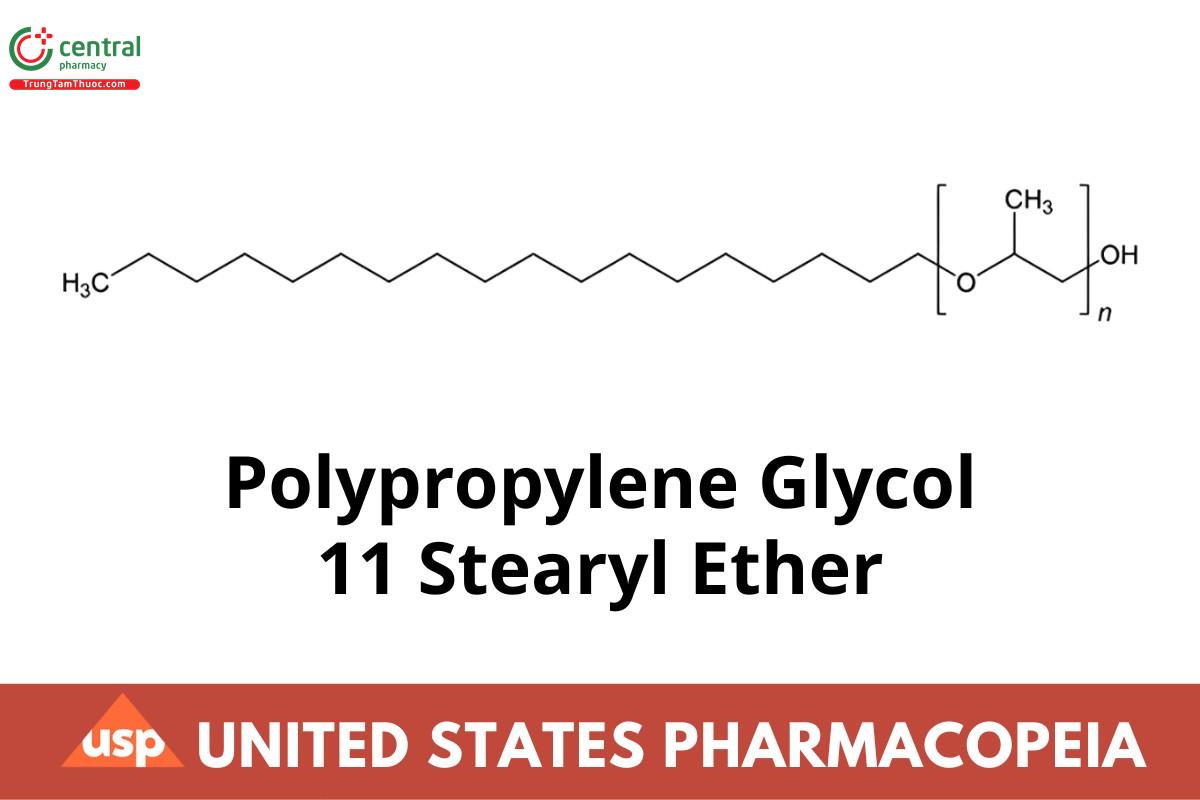

Polypropylene Glycol 11 Stearyl Ether

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

- DEFINITION

- IDENTIFICATION

- ASSAY

- IMPURITIES

- SPECIFIC TESTS

- FATS AND FIXED OILS (401), Procedures, Acid Value

- FATS AND FIXED OILS (401), Procedures, Hydroxyl Value

- FATS AND FIXED OILS (401), Procedures, lodine Value, Method I

- FATS AND FIXED OILS (401), Procedures, Peroxide Value

- FATS AND FIXED OILS (401), Procedures, Saponification Value

- WATER DETERMINATION (921), Method I, Method Ic

- ADDITIONAL REQUIREMENTS

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

C18H38O(C3H6O)n, where the average value ofnis 11.

Poly[oxy(methyl-1,2-ethanediyl)], α-octadecyl-ω-hydroxy-;

Polypropylene glycol monooctadecyl ether;

Polyoxypropylene 11 stearyl ether

CAS RN®: 25231-21-4.

Change to read:

1 DEFINITION

Polypropylene Glycol 11 Stearyl Ether is a mixture of ethers of polypropylene glycol with linear alcohols, mainly stearyl alcohol, obtained by the reaction of stearyl alcohol with propylene oxide. It may contain some free polypropylene glycol and various amounts of free stearyl alcohol. The number of moles of propylene oxide reacted per mole of stearyl alcohol is 11 (nominal value). It contains NLT 96.0% and NMT 104.0% of polypropylene glycol 11 stearyl ether, calculated on the anhydrous basis(NF 1-May-2023). A suitable antioxidant may be added.

2 IDENTIFICATION

A. SPECTROSCOPIC IDENTIFICATION TESTS (197), Infrared Spectroscopy: 197A

B. It meets the requirements in Specific Tests for Fats and Fixed Oils (401), Procedures, Hydroxyl Value.

C. It meets the requirements in Specific Tests for Fats and Fixed Oils (401), Procedures, Saponification Value.

D. VISCOSITY

Analysis: Follow the procedures in Viscosity-Capillary Methods (911), Method 1. Immerse the viscometer in a water or oil bath stabilized at 20°. The measurement can also be carried out with a rotational rheometer or viscometer1 following the procedures in Viscosity-Rotational Methods (912), Method III. The temperature under the test condition is at 20°. The samples are tested in the controlled stress mode with a shear stress increasing from 0-100 Pa for 120 s with 100 measured points. Each sample is equilibrated in the measuring gap of 0.052 mm for 60 s. The dynamic viscosity is determined from the slope of the flow curve.

Acceptance criteria: 83-95 mPa·s

Add the following:

3 ASSAY

3.1 PROCEDURE

Solution A: 0.05% 98 percent formic acid in a mixture of methanol and acetonitrile (80:20)

Solution B: Tetrahydrofuran

Mobile phase: A mixture of Solution A and Solution B (95:5)

System suitability solution: 1.0 mg/mL of USP Polypropylene Glycol 11 Stearyl Ether RS and 0.02 mg/mL of USP Stearyl Alcohol RS in Mobile phase

Standard solution: 1.0 mg/mL of USP Polypropylene Glycol 11 Stearyl Ether RS in Mobile phase

Sample solution: 1.0 mg/mL of Polypropylene Glycol 11 Stearyl Ether in Mobile phase

3.2 Chromatographic system

(See Chromatography (621), System Suitability.)

Mode: LC

Detector: Refractive index

Column: 4.6-mm × 25-cm; 5-µm packing L7

Temperatures

Column: 30°

Detector: 30°

Flow rate: 1.0 mL/min

Injection volume: 20 µL

Run time: 20 min

3.3 System suitability

Samples: System suitability solution and Standard solution

[NOTE-The approximate relative retention time of stearyl alcohol with reference to polypropylene glycol 11 stearyl ether is 0.8.]

Suitability requirements

Resolution: NLT 1.5 between stearyl alcohol and polypropylene glycol 11 stearyl ether, System suitability solution

Tailing factor: NMT 2.0 for polypropylene glycol 11 stearyl ether, Standard solution

Relative standard deviation: NMT 1% for polypropylene glycol 11 stearyl ether, Standard solution

3.4 Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of polypropylene glycol 11 stearyl ether in the portion of Polypropylene Glycol 11 Stearyl Ether taken:

Result = (rU/rS) x (CS/CU) x 100

rU = peak area of polypropylene glycol 11 stearyl ether from the Sample solution

rS = peak area of polypropylene glycol 11 stearyl ether from the Standard solution

CS = concentration of USP Polypropylene Glycol 11 Stearyl Ether RS in the Standard solution (mg/mL)

CU = concentration of Polypropylene Glycol 11 Stearyl Ether in the Sample solution (mg/mL) on (mg/mL)

Acceptance criteria: 96.0%-104.0% on the anhydrous basis (NF 1-May-2023)

4 IMPURITIES

4.1 RESIDUE ON IGNITION (281)

Sample: 1.0 g

Acceptance criteria: NMT 0.3%

4.2 LIMIT OF FREE PROPYLENE OXIDE

Propylene oxide stock solution: Accurately weigh 45 g of polyethylene glycol 200 kept at 8°-15° and add 1.0 g of propylene oxide. Carefully mix the solution by swirling, ensuring a homogenous solution. Add further polyethylene glycol 200 until the total weight is 50.0 g and mix again. Allow the solution to reach room temperature. Dilute 0.5 g of this solution up to 100.0 mL in water. Note the exact mass. [NOTE-Propylene oxide stock solution is stable for 1 month, if stored at -20°.]

Propylene oxide standard solution: Dilute 10.0 mL of Propylene oxide stock solution with water to 100.0 mL.

Propionaldehyde stock solution: Accurately weigh 0.1 g of propionaldehyde into a volumetric flask and dilute with water to 100.0 mL.

Sample solution A: Accurately weigh 1.0 g of Polypropylene Glycol 11 Stearyl Ether into a 20-mL headspace vial. Add 0.5 mL of water kept at 8°-15° and seal the vial immediately with a polytetrafluoroethylene (PTFE)-coated silicon membrane and an aluminum cap. Mix carefully.

Sample solution B: Accurately weigh 1.0 g of Polypropylene Glycol 11 Stearyl Ether into a 20-mL headspace vial. Add 0.5 mL of Propylene oxide standard solution kept at 8°-15° and seal the vial immediately with a PTFE-coated silicon membrane and an aluminum cap. Mix carefully.

Reference solution: Add 50.0 mL of Propylene oxide standard solution kept at 8°-15° to a volumetric flask and add 0.5 mL of Propionaldehyde stock solution kept at 8°-15°. Dilute with water to 100.0 mL. Transfer 0.5 mL of this solution into a 20-mL headspace vial and seal the vial immediately with a PTFE-coated silicon membrane and an aluminum cap.

Chromatographic system

(See Chromatography (621), System Suitability.)

Mode: GC, equipped with a headspace injector

Detector: Flame ionization

Column: 0.32-mm x 60-m fused-silica; coated with 5-um film of phase G1

Temperatures

Injection port: 150°

Detector: 250°

Column: See Table 1.

Table 1

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

| 50 | — | 50 | 5 |

| 50 | 5 | 180 | 0 |

| 180 | 29.4 | 230 | 5 |

Carrier gas: Helium

Flow rate: 2.6 mL/min

Injection volume: A suitable volume (e.g., 1.0 mL) of the gaseous phase of Sample solution A, Sample solution B, and Reference solution (injected separately)

Injection type: Split, split ratio 10:1

Static headspace conditions: The vials are maintained at 90° for 45 min before headspace injection. [NOTE-The static headspace conditions can be optimized/adjusted according to the instruments used, if needed.]

System suitability

Sample: Reference solution

[NOTE-The relative retention time of propionaldehyde with reference to propylene oxide is approximately 0.96.]

Suitability requirements

Resolution: NLT 1.5 between the propionaldehyde and propylene oxide peaks

Signal-to-noise ratio: NLT 10, determined for the propylene oxide peak

Analysis

Samples: Sample solution A and Sample solution B

Calculate the content of propylene oxide in parts per million (ppm) in the portion of Polypropylene Glycol 11 Stearyl Ether taken:

Result = (A1 x m x 5)/[(A2 x M1) - (A1 x M2)]

A1 = peak area of propylene oxide from Sample solution A

m = mass of propylene oxide used to prepare the Propylene oxide stock solution (g)

A2 = peak area of propylene oxide from Sample solution B

M1 = mass of Polypropylene Glycol 11 Stearyl Ether in Sample solution A (g)

M2 = mass of Polypropylene Glycol 11 Stearyl Ether in Sample solution B (g)

Acceptance criteria: NMT 5 ppm

5 SPECIFIC TESTS

5.1 FATS AND FIXED OILS (401), Procedures, Acid Value

Analysis: Accurately weigh 20 g of the sample into a wide-necked flask. To prepare the solvent, heat 50 mL of Ethanol to the boiling point for 15-20 s in a second flask and add 0.5 mL of phenolphthalein TS. Neutralize the solvent with 0.1 N sodium hydroxide VS while keeping the temperature above 70°. Add the neutralized solvent to the sample flask and mix thoroughly. Bring the contents to a boil and titrate with 0.1 N sodium hydroxide VS until a single drop produces a slight but definite color change, from colorless to pink, persisting for at least 15 s. For additional information not mentioned here, follow the procedure as directed in the chapter.

Acceptance criteria: NMT 2.0

5.2 FATS AND FIXED OILS (401), Procedures, Hydroxyl Value

Pyridine-acetic anhydride reagent: Just before use, mix 85 volumes of freshly opened or freshly distilled pyridine with 15 volumes of freshly opened or freshly distilled acetic anhydride.

Analysis: Accurately weigh about 1.5 g of the sample into a flat-bottomed flask and pipet 5.0 mL of Pyridine-acetic anhydride reagent. Attach an air condenser to the flask and place the solution onto the sand bath2 for refluxing for 60 min. The sand bath temperature must be set such that the sample reflux temperature is between 85° and 100°. Add 10 mL of water through the top of the condenser, swirl the flask and contents, and allow the flask to remain on the sand bath for a further 5-10 min. Remove the flask from the sand bath and allow it to cool to room temperature. Wash down the condenser with 30 mL of ethanol. Add 0.5 mL of phenolphthalein TS to the flask. Titrate with 0.5 N sodium hydroxide VS until a single drop produces a slight but definite color change, from colorless to pink, persisting for at least 15 s. Perform the test in duplicate, along with a blank. For the blank, repeat the test procedure but omit the sample. Calculate the average hydroxyl value for the sample from the two determinations. For additional information not mentioned here, follow the procedure as directed in the chapter.

Acceptance criteria: 60-77

5.3 FATS AND FIXED OILS (401), Procedures, lodine Value, Method I

Analysis: Follow the procedure as directed in the chapter, except use 15 mL of chloroform to dissolve the sample instead of 10 mL and the volume of potassium iodide TS added in the process is 6 mL instead of 30 mL.

Acceptance criteria: NMT 3.0

5.4 FATS AND FIXED OILS (401), Procedures, Peroxide Value

Analysis: Accurately weigh about 10 g of Polypropylene Glycol 11 Stearyl Ether. Follow the procedure as directed in the chapter, except use 0.1 N sodium thiosulfate VS in the titration instead of 0.01 N sodium thiosulfate solution.

Acceptance criteria: NMT 5.0

5.5 FATS AND FIXED OILS (401), Procedures, Saponification Value

Analysis: Accurately weigh about 20 g of Polypropylene Glycol 11 Stearyl Ether. Follow the procedure as directed in the chapter, except that as the endpoint approaches in the titration reheat the solution to ensure that the endpoint (color change from pink to colorless) is achieved at the boiling point of the solution.

Acceptance criteria: NMT 3.0

5.6 WATER DETERMINATION (921), Method I, Method Ic

NMT 0.7%

6 ADDITIONAL REQUIREMENTS

6.1 PACKAGING AND STORAGE

Preserve in tight containers.

Change to read:

6.2 USP REFERENCE STANDARDS (11)

USP Polypropylene Glycol 11 Stearyl Ether RS

USP Stearyl Alcohol RSA (NF 1-May-2023)

LABELING: Label to indicate the names and proportions of any added antioxidant. FICIAL

1 Haake RheoStress 6000, Thermo Scientific, D-Karlsruhe, with a cone/plate geometry (diameter of 35 mm and cone angle of 1°) and other equivalent instruments can be used.

2 Other types of heating devices may also be used if suitable for the intended use.