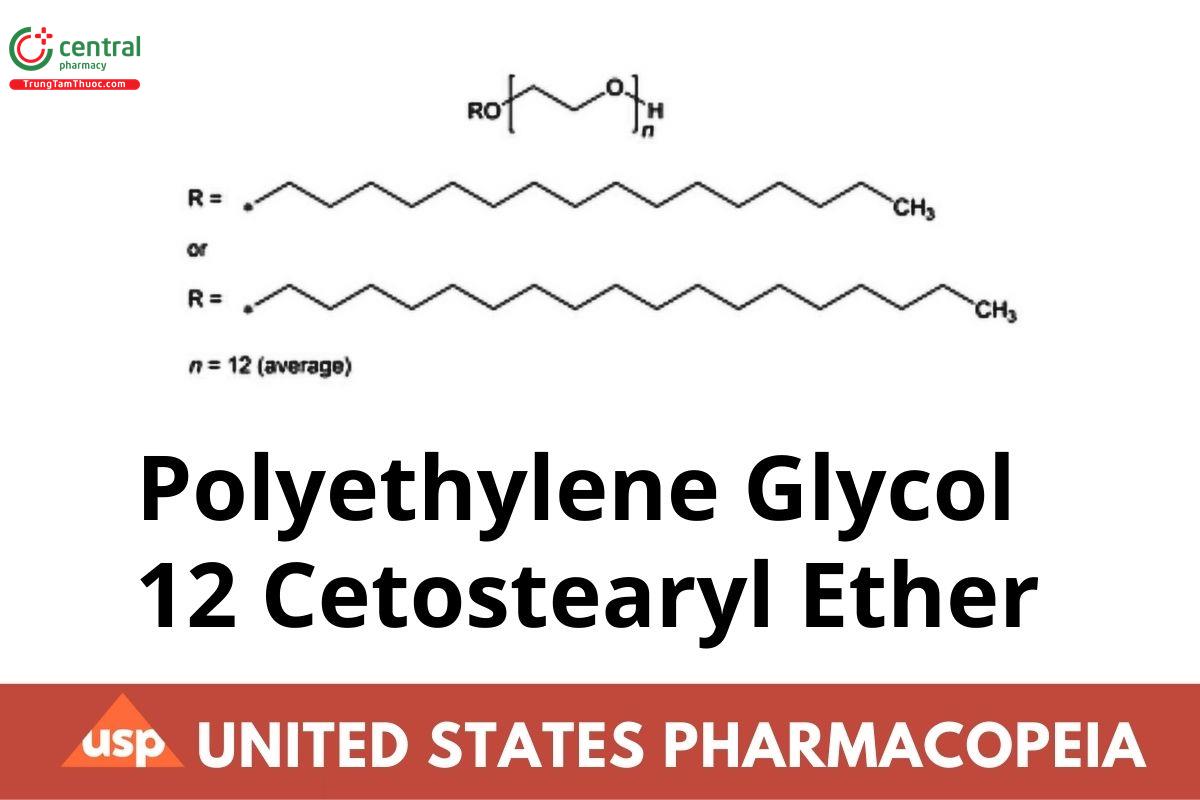

Polyethylene Glycol 12 Cetostearyl Ether

If you find any inaccurate information, please let us know by providing your feedback here

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

Polyethylene Glycol 12 Cetostearyl Ether is a mixture of ethers of mixed polyethylene glycols with linear fatty alcohols, mainly cetostearyl alcohol. It may contain some free polyethylene glycols and various amounts of free cetostearyl alcohol. The number of moles of ethylene oxide reacted per mole of cetostearyl alcohol is 12 (nominal value).

2 IDENTIFICATION

A. SPECTROSCOPIC IDENTIFICATION TESTS (197), Infrared Spectroscopy: 197A

B. HYDROXYL VALUE (ERR 1-A-2023) It meets the requirements in Specific Tests for Fats and Fixed Oils (401), Procedures. Hydroxyl Value.

C. TEST FOR STEARYL ALCOHOL

Standard solution: Dissolve 25 mg of USP Stearyl Alcohol RS in methanol and dilute with the same solvent to 25 mL.

Sample solution: Dissolve about 10.0 g of the substance to be examined in a mixture of 1 volume of water and 9 volumes of methanol and dilute with the same mixture of solvents to 75 mL. Add 60 mL of hexane and shake for 3 min. The formation of foam can be reduced by the addition of 2-3 drops of alcohol. Filter the upper layer through anhydrous sodium sulfate, wash the filter with 3 quantities, each with 10 mL of hexane, and evaporate the combined filtrates to dryness. Dissolve 0.05 g of the residue in 10 ml of methanol (the solution may be opalescent).

Chromatographic system

(See Chromatography (621), General Procedures, Thin-Layer Chromatography and Thin-Layer Chromatographic Identification Test (201).)

Mode: TLC

Adsorbent: Chromatographic silica gel with an average particle size of 5 µm (HPTLC plate)1

Developing solvent system: Ethyl acetate

Application volume: 20 µL

Temperature: Ambient

Developing distance: 15 cm

Spray reagent: Dissolve 0.5 g of vanillin in 50 mL of alcohol, and dilute with sulfuric acid to 100 mL

Analysis

Samples: Apply the Standard solution and Sample solution, and allow the spots to dry. Develop the chromatogram until the solvent front has moved about 15 cm. Remove the plate from the developing chamber, mark the solvent front, and allow the solvent to evaporate. Spray with Spray reagent; allow to dry in air; heat at about 130° for 15 min, and allow to cool in air.

Acceptance criteria: The chromatogram obtained with the Sample solution shows several spots. The retardation factor (RF) of one of these spots corresponds to the R of the principal spot in the chromatogram obtained with the Standard solution.

D.

Diluted hydrochloric acid: Dilute 20 g of hydrochloric acid with water to 100 mL..

Barium chloride solution: Prepare a 61-g/L solution of barium chloride in water.

Phosphomolybdic acid solution: Prepare a 100-g/L solution of phosphomolybdic acid in water.

Analysis: Dissolve or disperse the Sample in 5 mL (ERR 1-Aug-2023) alcohol. Add 2 mL of water, 10 mL of Diluted hydrochloric acid, 10 mL of Barium chloride solution, and 10 mL of Phosphomolybdic acid solution.

Sample: 0.1 g

Acceptance criteria: A precipitate is formed.

3 IMPURITIES

RESIDUE ON IGNITION (281): NMT 0.2%

ETHYLENE OXIDE AND DIOXANE (228), Method /

Acceptance criteria

For ethylene oxide: NMT 1 ppm

For dioxane: NMT 10 ppm

4 SPECIFIC TESTS

FATS AND FIXED OILS (401), Procedures, Acid Value, Method I

Analysis: Accurately weigh 5.0 g of the sample. [NOTE-Petroleum ether with a 100°-120° boiling range can be used to replace ether in the test.]

Acceptance criteria: NMT 1.0.

FATS AND FIXED OILS (401), Procedures. Hydroxyl Value: 67-77

FATIS AND FIXED Ons (401), Procedures. Saponification Value

Analysis: Accurately weigh 10.0 g of the sample.

Acceptance criteria: NMT 3.0

FATS AND FIXED OILS (401), Procedures, lodine Value. Method

Analysis: Accurately weigh 1.0 g of the sample.

Acceptance criteria: NMT 2.0

WATER DETERMINATION (921), Method I

Analysis: Accurately weigh 2.0 g of the sample...

Acceptance criteria: NMT 3.0%

ALKALINITY

Sample: 2.0 g

Bromothymol blue solution: Dissolve 50 mg of bromothymol blue indicator in a mixture of 4 ml of 0.02 N sodium hydroxide and 20 ml. of alcohol, and dilute with water to 100 mL.

Analysis: Dissolve the sample in a hot mixture of 10 mL of alcohol and 10 ml of water. Add 0.1 mL of Bromothymol blue solution.

Acceptance criteria: NMT 0.5 mL of 0.1. N hydrochloric acid is required to change the color of the indicator to yellow.

5 ADDITIONAL REQUIREMENTS

PACKAGING AND STORAGE: Preserve in tight containers, at ambient temperature.