Polyethylene Glycol

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

- DEFINITION

- ASSAY

- IMPURITIES

- Residue on Ignition 〈281〉

- Limit of Free Ethylene Oxide and 1,4-Dioxane

- Limit of Ethylene Glycol and Diethylene Glycol (for Polyethylene Glycol having a nominal molecular weight less than 450)

- Limit of Ethylene Glycol and Diethylene Glycol (for Polyethylene Glycol having a nominal molecular weight of 450 or more but NMT 1000)

- SPECIFIC TESTS

- ADDITIONAL REQUIREMENTS

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

Change to read:

(ERR 1-Feb-2020)

Poly(oxy-1,2-ethanediyl), α-hydro-ω-hydroxy-;

Polyethylene glycol

CAS RN®: 25322-68-3.

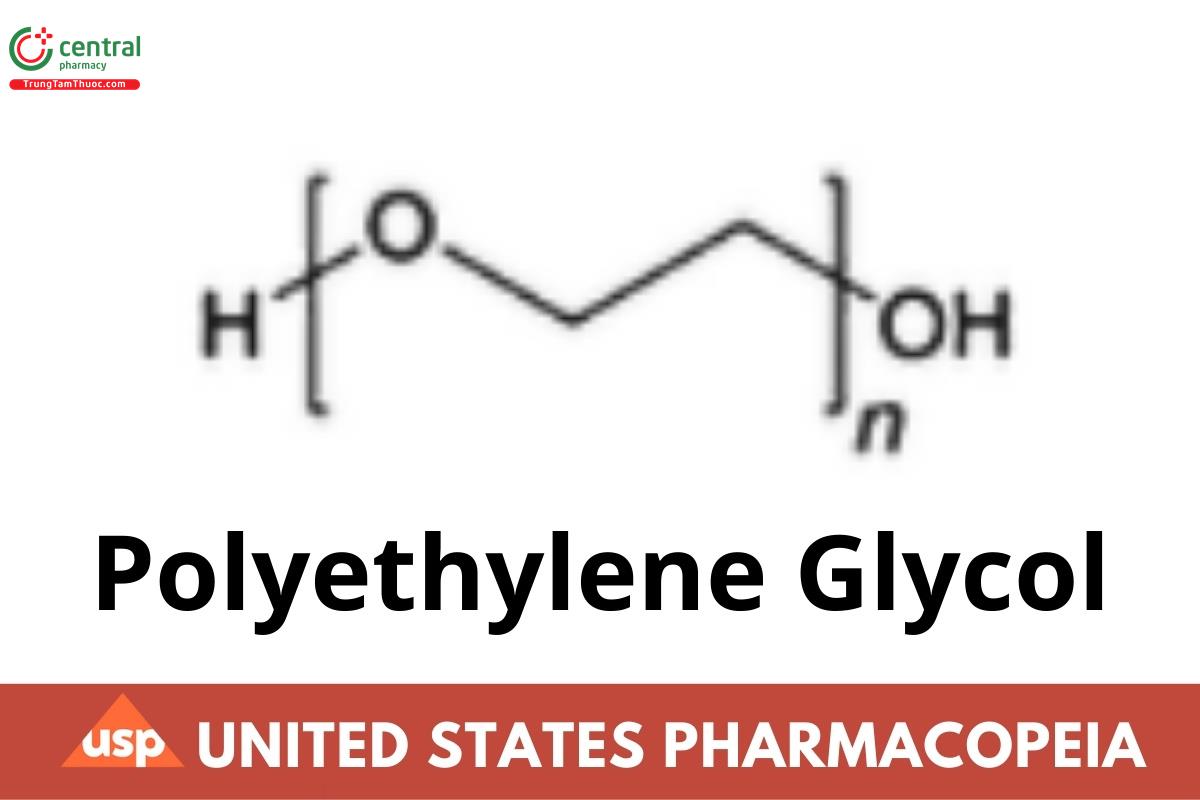

1 DEFINITION

Polyethylene Glycol is an addition polymer of ethylene oxide and water, represented by the formula H(OCH2CH2)nOH, in which n represents the average number of oxyethylene groups. The average molecular weight is NLT 95.0% and NMT 105.0% of the labeled nominal value if the labeled nominal value is less than 1000; it is NLT 90.0% and NMT 110.0% of the labeled nominal value if the labeled nominal value is between 1000 and 7000; and it is NLT 87.5% and NMT 112.5% of the labeled nominal value if the labeled nominal value is more than 7000. It may contain a suitable antioxidant.

2 ASSAY

2.1 Average Molecular Weight

Phthalic anhydride solution: Place 49.0 g of phthalic anhydride into an amber bottle, and dissolve in 300 mL of pyridine from a freshly opened bottle or pyridine that has been freshly distilled over phthalic anhydride. Shake vigorously until completely dissolved. Add 7 g of imidazole, swirl carefully to dissolve, and allow to stand for 16 h before using.

Sample solution for liquid polyethylene glycols: Carefully introduce 25.0 mL of the Phthalic anhydride solution into a dry, heat-resistant pressure bottle. Add an amount of the specimen equivalent to its expected average molecular weight divided by 160. Insert the stopper in the bottle, and wrap it securely in a cloth bag.

Sample solution for solid polyethylene glycols: Carefully introduce 25.0 mL of Phthalic anhydride solution into a dry, heat-resistant pressure bottle. Add an amount of the specimen equivalent to its expected molecular weight divided by 160; however, because of limited solubility, do not use more than 25 g. Add 25 mL of pyridine, from a freshly opened bottle or pyridine that has been freshly distilled over phthalic anhydride. Swirl to dissolve, insert the stopper in the bottle, and wrap it securely in a cloth bag.

Blank: 25.0 mL of Phthalic anhydride solution plus any additional pyridine added to the bottle.

Analysis: Immerse the bottle in a water bath maintained at a temperature between 96° and 100°, to the same depth as that of the mixture in the bottle. Remove the bottles from the bath after 5 min and, without unwrapping, swirl for 30 s to homogenize. Heat in the water bath for 30 min (60 min for polyethylene glycols having molecular weights of 3000 or more), then remove from the bath, and allow to cool to room temperature. Uncap the bottle carefully to release any pressure, remove from the bag, add 10 mL of water, and swirl thoroughly. Wait 2 min, add 0.5 mL of a solution of phenolphthalein in pyridine (1 in 100), and titrate with 0.5 N sodium hydroxide VS to the first pink color that persists for 15 s. Perform a blank determination.

Calculate the average molecular weight taken:

Result = (2000 × W) /[(VB - VS) × N]

W = weight of Polyethylene Glycol taken for the Sample solution (g)

VB = volume of 0.5 N sodium hydroxide consumed by the Blank (mL)

VS = volume of 0.5 N sodium hydroxide consumed by the specimen (mL)

N = normality of the sodium hydroxide solution

Acceptance criteria: See Table 1.

Table 1

Label Claim (Nominal Value) | Acceptance Criteria (%) |

<1000 | 95.0-105.0 |

1000-7000 | 90.0-110.0 |

>7000 | 87.5-112.5 |

3 IMPURITIES

3.1 Residue on Ignition 〈281〉

Sample: 25 g

Analysis: Proceed as directed, using a platinum dish, and moistening the residue with 2 mL of sulfuric acid.

Acceptance criteria: NMT 0.1%

3.2 Limit of Free Ethylene Oxide and 1,4-Dioxane

Stripped polyethylene glycol 400: Into a 5000-mL, 3-neck, round-bottom flask equipped with a stirrer, a gas dispersion tube, and a vacuum outlet, place 3000 g of polyethylene glycol 400. At room temperature, evacuate the flask carefully to a pressure of less than 1 mm of mercury, applying the vacuum slowly while observing for excessive foaming due to entrapped gases. After any foaming has subsided and while stirring continuously, sparge with nitrogen, allowing the pressure to rise to 10 mm of mercury. Continue stripping for a minimum of 1 h. Completeness of the stripping procedure should be verified by making a headspace injection of the Stripped polyethylene glycol 400.

[Note—The 10-mm value is a guideline. Deviations from this value affect only the total time required to strip polyethylene glycol 400.]

Shut off the vacuum pump, and bring the flask pressure back to atmospheric pressure while maintaining nitrogen sparging. Remove the gas dispersion tube with the gas still flowing, then turn off the gas flow. Transfer Stripped polyethylene glycol 400 to a suitable nitrogen-filled container.

Standard solution: Transfer 4.90 g of Stripped polyethylene glycol 400 to a tared 22-mL pressure headspace vial that can be sealed. Add 48 µL of 1,4-dioxane, equivalent to 50 mg of 1,4-dioxane, from a syringe; seal, and cap the vial.

[Caution—Ethylene oxide and 1,4-dioxane are toxic and flammable. Prepare these solutions in a well-ventilated fume hood.]

Using the special handling described in the following, complete the preparation. Ethylene oxide is a gas at room temperature. It is usually stored in a lecture-type gas cylinder or small metal pressure bomb. Chill the cylinder in a refrigerator before use. Transfer 5 mL of the liquid ethylene oxide to a 100-mL beaker chilled in wet ice. Using a gas-tight syringe that has been chilled in a refrigerator, transfer 57 µL of the liquid ethylene oxide, equivalent to 50 mg of ethylene oxide, to the mixture contained in the headspace vial, and mix. With the aid of a syringe, transfer 2 mL of this solution to a 5-mL beaker. Transfer 1.0 mL of this solution to a 100-mL volumetric flask, and dilute with Stripped polyethylene glycol 400 to volume. Transfer 10 mL of this solution to a 100-mL volumetric flask, dilute with Stripped polyethylene glycol 400 to volume, and mix to obtain a Standard solution having known concentrations of 10 µg/g for both ethylene oxide and 1,4-dioxane. Transfer 1.0 mL of the Standard solution to a 22-mL pressure headspace vial, seal with a silicone septum with or without a pressure relief star spring and a pressure relief safety aluminum sealing cap, and crimp the cap closed with a cap-sealing tool.

System suitability solution: Transfer 4.90 g of Stripped polyethylene glycol 400 to a 22-mL pressure headspace vial. Pipet 50 µL of acetaldehyde into the vial. Using the special handling described in the Standard solution, transfer 50.0 µL of liquid ethylene oxide into the vial. Immediately seal the vial, and shake. Transfer 1.0 mL of this solution to a 100-mL volumetric flask, and dilute with Stripped polyethylene glycol 400 to volume. Transfer 10.0 mL of this solution to a 100-mL volumetric flask, and dilute with Stripped polyethylene glycol 400 to volume. Transfer 1.0 mL of the System suitability solution to a 22-mL pressure headspace vial. Seal, cap, and crimp as directed for the Standard solution.

Sample solution: Transfer 1.0 g of Polyethylene Glycol to a 22-mL pressure headspace vial. Seal, cap, and crimp as directed in the Standard solution.

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: Headspace GC (balanced pressure automatic headspace sampler)

Detector: Flame ionization

Column: 0.32-mm × 50-m fused-silica capillary; bonded with 5-µm film of phase G27

Temperatures

Injection port: 85°

Detector: 250°

Column: See Table 2.

Table 2

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

| 70 | 10 | 250 | - |

Carrier gas: Helium

Flow rate: 2.9 mL/min

Injection volume: 1.0 mL of headspace using a 2-mL gas syringe preheated in an oven at 90°

System suitability

Sample: System suitability solution

[Note—The relative retention times for acetaldehyde and ethylene oxide are about 0.9 and 1.0, respectively.]

Suitability requirements

Resolution: NLT 1.3 between the acetaldehyde and ethylene oxide peaks

Analysis

Samples: Standard solution and Sample solution

[Note—The relative retention times for ethylene oxide and 1,4-dioxane are about 1.0 and 3.4, respectively.]

Place the vials containing the Standard solution and the Sample solution into the automated sampler, and heat the vials at a temperature of 80° for 30 min.

[Note—A headspace apparatus that automatically transfers the measured amount of headspace may be used to perform the injection.]

Acceptance criteria: The peak areas for ethylene oxide and 1,4-dioxane of the Sample solution are NMT those of the corresponding peaks of the Standard solution corresponding to NMT 10 µg/g of ethylene oxide and NMT 10 µg/g of 1,4-dioxane.

3.3 Limit of Ethylene Glycol and Diethylene Glycol (for Polyethylene Glycol having a nominal molecular weight less than 450)

Standard solution: 0.5 mg/mL each of ethylene glycol and diethylene glycol in water

Sample solution: 400 mg/mL of Polyethylene Glycol in water

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: GC

Detector: Flame ionization

Column: 3-mm × 1.5-m stainless steel; packing of 12% G13 on support S1NS

Temperatures

Injection port: 250°

Detector: 280°

Column: 140°

Carrier gas: Nitrogen or another suitable inert gas

Flow rate: 50 mL/min

Injection volume: 2.0 µL

Analysis

Samples: Standard solution and Sample solution

[Note—The elution order is ethylene glycol followed by diethylene glycol.]

Calculate the percentage of ethylene glycol in the portion of Polyethylene Glycol taken:

Result = (rU1/rS1) × (CS1/CU) × 100

rU1 = peak height of ethylene glycol from the Sample solution

rS1 = peak height of ethylene glycol from the Standard solution

CS1 = concentration of ethylene glycol in the Standard solution (mg/mL)

CU = concentration of Polyethylene Glycol in the Sample solution (mg/mL)

Calculate the percentage of diethylene glycol in the portion of Polyethylene Glycol taken:

Result = (rU2/rS2) × (CS2/CU) × 100

rU2 = peak height of diethylene glycol from the Sample solution

rS2 = peak height of diethylene glycol from the Standard solution

CS2 = concentration of diethylene glycol in the Standard solution (mg/mL)

CU = concentration of Polyethylene Glycol in the Sample solution (mg/mL)

Acceptance criteria: NMT 0.25% of the sum of ethylene glycol and diethylene glycol

3.4 Limit of Ethylene Glycol and Diethylene Glycol (for Polyethylene Glycol having a nominal molecular weight of 450 or more but NMT 1000)

Ceric ammonium nitrate solution: 6.25 g of ceric ammonium nitrate in 100 mL of 0.25 N nitric acid. Use within 3 days.

Standard stock solution: 2.5 mg/mL of diethylene glycol in freshly distilled acetonitrile and water (1:1)

Standard solution: Add 10.0 mL of the Standard stock solution to 15.0 mL of Ceric ammonium nitrate solution. Within 2–5 min, determine the absorbance of the Standard solution.

Sample stock solution: Dissolve 50.0 g of Polyethylene Glycol in 75 mL of diphenyl ether, previously warmed if necessary, just to melt the crystals, in a 250-mL distilling flask. Slowly distill at a pressure of 1–2 mm of mercury into a receiver graduated to 100 mL in 1-mL subdivisions, until 25 mL of distillate has been collected. Add 20.0 mL of water to the distillate, shake vigorously, and allow the layers to separate. Cool in an ice bath to solidify the diphenyl ether and facilitate its removal. Filter the separated aqueous layer, wash the diphenyl ether with 5.0 mL of ice-cold water, pass the washings through the filter, and collect the filtrate and washings in a 25-mL volumetric flask. Warm to room temperature, and dilute with water to volume, if necessary. Mix this solution with 25.0 mL of freshly distilled acetonitrile in a glass-stoppered, 125-mL conical flask.

Sample solution: Add 10.0 mL of the Sample stock solution to 15.0 mL of Ceric ammonium nitrate solution. Within 2–5 min, determine the absorbance of the Sample solution.

Blank: Mixture of 15.0 mL of Ceric ammonium nitrate solution and 10.0 mL of freshly distilled acetonitrile and water (1:1)

Instrumental conditions

(See Ultraviolet-Visible Spectroscopy 〈857〉.)

Mode: UV-Vis

Cell: 1 cm

Analytical wavelength: 450 nm

Analysis

Samples: Standard solution and Sample solution

Acceptance criteria: The absorbance of the Sample solution does not exceed that of the Standard solution, corresponding to NMT 0.25% of combined ethylene glycol and diethylene glycol.

4 SPECIFIC TESTS

pH 〈791〉

Sample solution: 5.0 g of Polyethylene Glycol in 100 mL of carbon dioxide-free water. Add 0.30 mL of saturated potassium chloride solution.

Acceptance criteria: 4.5–7.5

Completeness and Color of Solution: A solution of 5 g of Polyethylene Glycol in 50 mL of water is colorless; it is clear for liquid grades and NMT slightly hazy for solid grades.

Viscosity—Capillary Methods 〈911〉: Determine the viscosity by using a capillary viscometer giving a flow time of NLT 200 s and using a liquid bath maintained at 98.9 ± 0.3° (210° F). The viscosity is within the limits specified in Table 3. For a polyethylene glycol not listed in the table, calculate the limits by interpolation.

Table 3

| Nominal Average Molecular Weight | Viscosity Range, Centistokes | Nominal Average Molecular Weight | Viscosity Range, Centistokes |

| 200 | 3.9–4.8 | 2400 | 49–65 |

| 300 | 5.4–6.4 | 2500 | 51–70 |

| 400 | 6.8–8.0 | 2600 | 54–74 |

| 500 | 8.3–9.6 | 2700 | 57–78 |

| 600 | 9.9–11.3 | 2800 | 60–83 |

| 700 | 11.5–13.0 | 2900 | 64–88 |

| 800 | 12.5–14.5 | 3000 | 67–93 |

| 900 | 15.0–17.0 | 3250 | 73–105 |

| 1000 | 16.0–19.0 | — | — |

| 1100 | 18.0–22.0 | 3500 | 87–123 |

| 1200 | 20.0–24.5 | 3750 | 99–140 |

| 1300 | 22.0–27.5 | 4000 | 110–158 |

| 1400 | 24–30 | 4250 | 123–177 |

| 1450 | 25–32 | 4500 | 140–200 |

| 1500 | 26–33 | 4750 | 155–228 |

| 1600 | 28–36 | 5000 | 170–250 |

| 1700 | 31–39 | 5500 | 206–315 |

| 1800 | 33–42 | 6000 | 250–390 |

| 1900 | 35–45 | 6500 | 295–480 |

| 2000 | 38–49 | 7000 | 350–590 |

| 2100 | 40–53 | 7500 | 405–735 |

| 2200 | 43–56 | 8000 | 470–900 |

| 2300 | 46–60 | — | — |

[Note—Polyethylene Glycol 3350 is listed in the USP official monographs section to reflect its use as both an active and inactive ingredient.]

5 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in tight containers.

Labeling: Label it to state, as part of the official title, the average nominal molecular weight of the Polyethylene Glycol. Label it to indicate the name and quantity of any added antioxidant.