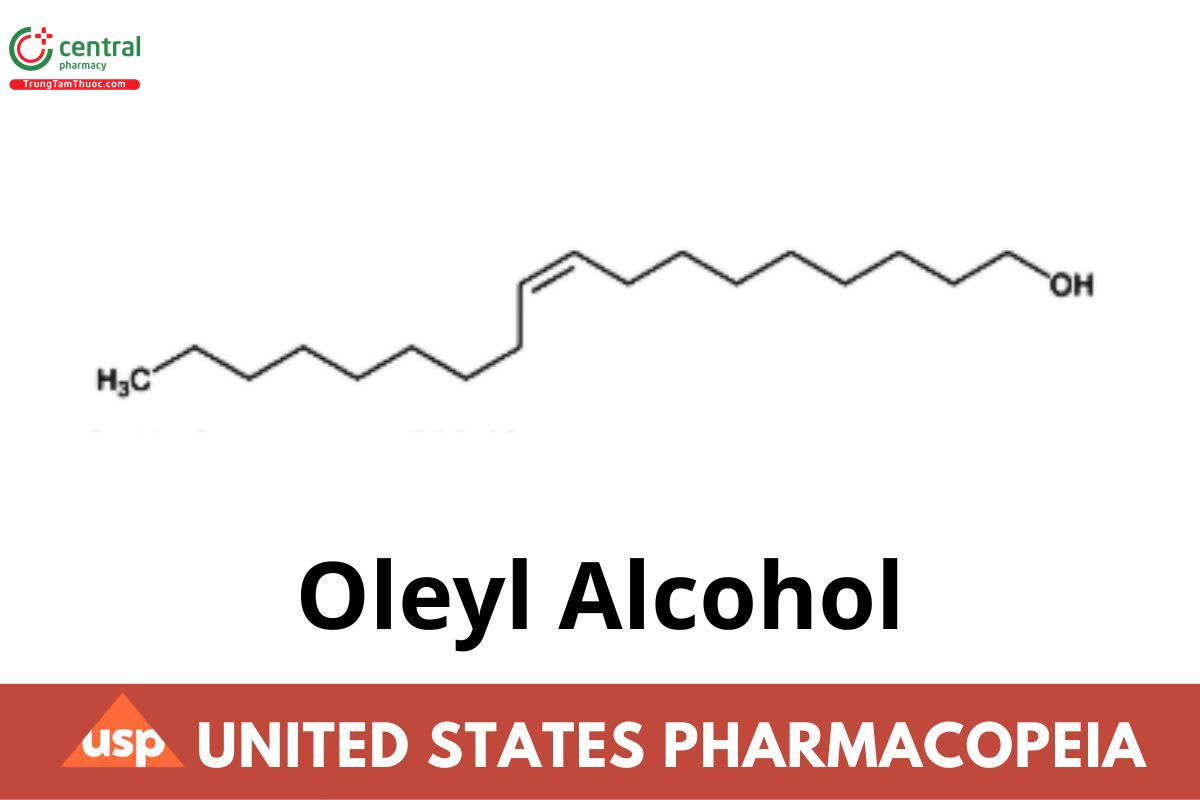

Oleyl Alcohol

If you find any inaccurate information, please let us know by providing your feedback here

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

Oleyl Alcohol is a mixture of unsaturated and saturated high molecular weight fatty alcohols consisting of 75.0%–102.0% of oleyl alcohol (C₁₈H₃₆O) and its isomers. It is obtained from sources of vegetable, animal, or synthetic origin. It may contain suitable stabilizers.

2 IDENTIFICATION

A. Chromatographic Identity

Analysis: Proceed as directed in the Assay.

Acceptance criteria: The retention time of the major peak of the Sample solution, excluding the solvent and internal standard peaks, corresponds to the oleyl alcohol peak of the System suitability solution.

3 ASSAY

Procedure

Internal standard solution: 1 mg/mL of 1-pentadecanol (internal standard) in ethanol

System suitability solution: Prepare 1 mg/mL each of USP Cetyl Alcohol RS, USP Stearyl Alcohol RS, and USP Oleyl Alcohol RS in Internal standard solution, and heat the solution in a sealed container in a 50° water bath until all fatty alcohols are dissolved. Allow the solution to cool to room temperature, and mix well.

Standard solution: 1.0 mg/mL of USP Oleyl Alcohol RS in Internal standard solution

Sample solution: 1.0 mg/mL of Oleyl Alcohol in Internal standard solution

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: GC

Detector: Flame ionization

Column: 0.25-mm × 30-m fused silica capillary; coated with a 0.25-µm layer of phase G7

Temperatures

Table 1

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

|---|---|---|---|

| 60 | 20 | 180 | — |

| 180 | 10 | 220 | 5 |

Carrier gas: Hydrogen

Flow rate: 2.0 mL/min, constant [Ký tự không đọc được]ow mode

Injection volume: 1 µL

Injection type: Split injection; split ratio is 100:1

Liner: Single taper, low pressure drop liner with deactivated wool

Run time: 15 min

System suitability

Samples: System suitability solution and Standard solution

[Note—See Table 2 for the relative retention times.]

Table 2

| Component | Relative Retention Time |

|---|---|

| 1-Pentadecanol (internal standard) | 1.00 |

| Cetyl alcohol | 1.08 |

| Stearyl alcohol | 1.25 |

| Oleyl alcohol | 1.27 |

Suitability requirements

Resolution: NLT 30 between the cetyl alcohol and stearyl alcohol peaks; NLT 2.0 between the stearyl and oleyl alcohol peaks, System suitability solution

Tailing factor: 0.8–1.8 for the oleyl alcohol and 1-pentadecanol peaks, Standard solution

Relative standard deviation: NMT 1%, using the area ratio of oleyl alcohol to 1-pentadecanol, Standard solution

Analysis

Samples: Standard solution and Sample solution

The peak of elaidyl alcohol, which is an isomer of oleyl alcohol, can be resolved from the oleyl alcohol peak with a resolution of about 1, and with a relative retention time with reference to oleyl alcohol of 0.995. An additional small peak that may be observed on the peak tail of oleyl alcohol can be assigned to another oleyl alcohol isomer. If elaidyl alcohol is observed, a combination of both peaks of elaidyl alcohol and oleyl alcohol is used to determine oleyl alcohol content.

Calculate the percentage of oleyl alcohol (C₁₈H₃₆O) or its isomers in the portion of Oleyl Alcohol taken:

Result = (Rᵤ / Rₛ) × (Cₛ / Cᵤ) × 100

Rᵤ = peak response ratio of oleyl alcohol (or elaidyl alcohol) to the internal standard [peak response of oleyl alcohol (or elaidyl alcohol) / peak response of the internal standard] from the Sample solution

Rₛ = peak response ratio of oleyl alcohol to the internal standard (peak response of oleyl alcohol / peak response of the internal standard) from the Standard solution

Cₛ = concentration of USP Oleyl Alcohol RS in the Standard solution (mg/mL)

Cᵤ = concentration of Oleyl Alcohol in the Sample solution (mg/mL)

Acceptance criteria: 75.0%–102.0% for oleyl alcohol and its isomers

4 IMPURITIES

Residue on Ignition 〈281〉: NMT 0.1%, determined on 2 g

Limit of Related Fatty Alcohols

Resolution solution: Prepare 1 mg/mL each of USP Cetyl Alcohol RS, USP Stearyl Alcohol RS, USP Oleyl Alcohol RS, USP Linoleyl Alcohol RS, USP Linolenyl Alcohol RS, and USP Arachidyl Alcohol RS in ethanol. Heat the solution in a sealed container in a 50° water bath until all fatty alcohols are dissolved. Allow the solution to cool to room temperature, and mix well. Dilute the solution with Ethanol to obtain a solution containing 0.05 mg/mL each of USP Cetyl Alcohol RS, USP Stearyl Alcohol RS, USP Oleyl Alcohol RS, USP Linoleyl Alcohol RS, USP Linolenyl Alcohol RS, and USP Arachidyl Alcohol RS.

Sample solution: 1 mg/mL of Oleyl Alcohol in ethanol

Chromatographic system: Proceed as directed in the Assay, except use split injection with a split ratio of 5:1.

System suitability

Sample: Resolution solution

[Note—See Table 3 for the relative retention times.]

Table 3

| Component | Relative Retention Time |

|---|---|

| Cetyl alcohol | 0.85 |

| Stearyl alcohol | 0.99 |

| Oleyl alcohol | 1.00 |

| Linoleyl alcohol | 1.03 |

| Linolenyl alcohol | 1.06 |

| Arachidyl alcohol | 1.14 |

Suitability requirements

Resolution: NLT 30 between the cetyl alcohol and stearyl alcohol peaks; NLT 2.0 between the stearyl and oleyl alcohol peaks; NLT 6.0 between the oleyl alcohol and linoleyl alcohol peaks

Analysis

Samples: Resolution solution and Sample solution

Identify each related fatty alcohol peak in the Sample solution based on that in the Resolution solution.

Calculate the percentage of each related fatty alcohol in the portion of Oleyl Alcohol taken:

Result = (rᵤ / rₛ) × 100

rᵤ = peak response of each related fatty alcohol from the Sample solution

rₛ = sum of all the peak responses excluding peak responses due to solvent from the Sample solution

Acceptance criteria: See Table 4. Disregard peaks that are less than 0.05% for any unspeci[Ký tự không đọc được]ed impurities, and any peaks due to solvent.

Table 4

| Component | Acceptance Criteria, NMT (%) |

|---|---|

| Cetyl alcohol | 8.0 |

| Stearyl alcohol | 5.0 |

| Linoleyl alcohol | 7.0 |

| Linolenyl alcohol | 1.0 |

| Arachidyl alcohol | 1.0 |

5 SPECIFIC TESTS

Fats and Fixed Oils, Acid Value 〈401〉: NMT 1

Fats and Fixed Oils, Hydroxyl Value 〈401〉: 205–215

Fats and Fixed Oils, Peroxide Value 〈401〉: NMT 10.0

Water Determination, Method I 〈921〉: NMT 0.5%

6 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in well-[Ký tự không đọc được]lled, tight containers, and store at controlled room temperature.

Labeling: Label it to indicate whether it is derived from vegetable, animal, or synthetic sources. Indicate the names and amounts of any added stabilizers.

USP Reference Standards 〈11〉

USP Arachidyl Alcohol RS

USP Cetyl Alcohol RS

USP Linolenyl Alcohol RS

USP Linoleyl Alcohol RS

USP Oleyl Alcohol RS

USP Stearyl Alcohol RS