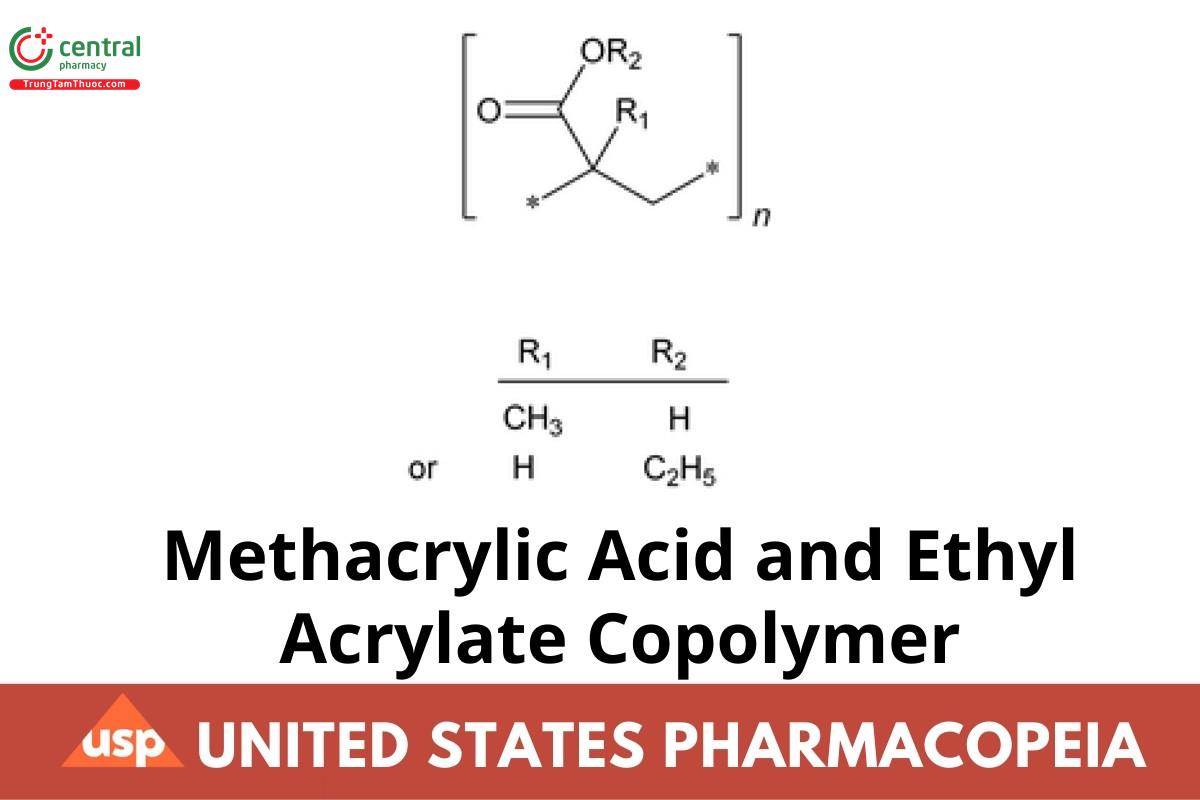

Methacrylic Acid and Ethyl Acrylate Copolymer

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

DOWNLOAD PDF HERE

1 DEFINITION

Methacrylic Acid and Ethyl Acrylate Copolymer consists of methacrylic acid and ethyl acrylate monomers arranged in a random distribution. Methacrylic acid units in Methacrylic Acid and Ethyl Acrylate Copolymer, previously dried, are NLT 46.0% and NMT 50.6%. It may contain suitable surface-active agents.

2 IDENTIFICATION

Change to read:

2.1 A.

Spectroscopic Identification Tests 〈197〉, Infrared Spectroscopy: 197K: Use USP Methacrylic Acid and Ethyl Acrylate Copolymer (1:1) RS (USP Methacrylic Acid Copolymer Type C RS) (ERR 1-Jul-2023) for Methacrylic Acid and Ethyl Acrylate Copolymer having a range of 46.0%– 50.6% for methacrylic acid units.

2.2 B.

It meets the requirements of the Assay.

3 ASSAY

3.1 Procedure

Sample: 1 g, previously dried

Analysis: Dissolve the Sample in 100 mL of neutralized acetone, and titrate with 0.1 N sodium hydroxide VS, determining the endpoint potentiometrically (see Titrimetry 〈541〉). Each mL of 0.1 N sodium hydroxide is equivalent to 8.609 mg of methacrylic acid (C4H6N2) units.

Acceptance criteria: 46.0%–50.6%

4 IMPURITIES

4.1 Residue on Ignition 〈281〉: NMT 0.4%

4.2 Limit of Methacrylic Acid and Ethyl Acrylate

Sodium perchlorate solution: 35 mg/mL of sodium perchlorate. This solution has a concentration of 0.25 M. Mobile phase: Add phosphoric acid dropwise to water to obtain a solution with a pH of 2.0. Prepare a mixture of this acidied water and methanol (80:20), and degas.

Standard solution: Dissolve 0.01 g of methacrylic acid and 0.01 g of ethyl acrylate in 5 mL of butanol, and add methanol to exactly 100 mL. Transfer 1.0 mL of this solution to a 100-mL volumetric ask. Dilute with methanol to volume. Mix 5.0 mL of this solution with 5.0 mL of Sodium perchlorate solution. This solution contains about 0.5 µg/mL each of methacrylic acid and ethyl acrylate.

Sample solution: Transfer about 3 g of Methacrylic Acid and Ethyl Acrylate Copolymer to a 50-mL volumetric ask, dilute with methanol to volume, and mix. Add 5.0 mL of this solution dropwise, while continuously stirring, to a beaker that contains 5.0 mL of Sodium perchlorate solution. Remove the precipitated polymer to obtain a clear supernatant by centrifugation (e.g., NLT 5000 × g for NLT 5 min). Use the clear supernatant.

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 202 nm

Column: 4.0-mm × 12.5-cm; 7-µm packing L1

Flow rate: 2 mL/min

Injection volume: 20 µL

System suitability

Sample: Standard solution

[Note—The relative retention times for methacrylic acid and ethyl acrylate are 1.0 and 2.6, respectively.]

Suitability requirements

Resolution: NLT 2.0 between methacrylic acid and ethyl acrylate

Relative standard deviation: NMT 5.0%

Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of each monomer (methacrylic acid or ethyl acrylate) in the portion of Methacrylic Acid and Ethyl Acrylate Copolymer taken:

Result = (ru/rs) × (C/W) × VF × D × F × 100

ru = peak response of the monomer (methacrylic acid or ethyl acrylate) from the Sample solution

rs = peak response of the monomer (methacrylic acid or ethyl acrylate) from the Standard solution

C = concentration of the monomer (methacrylic acid or ethyl acrylate) in the Standard solution (µg/mL)

W = weight of Methacrylic Acid and Ethyl Acrylate Copolymer taken to prepare the Sample solution (g)

VF = nal volume of the Sample solution, 10 mL

D = dilution factor for preparation of the Sample solution, 10

F = conversion factor, 10−6 g/µg

Acceptance criteria: NMT 0.01% for the total amount of monomers

5 SPECIFIC TESTS

5.1 Viscosity—Rotational Methods 〈912〉

Analysis: Place 254.6 g of isopropyl alcohol and 7.9 g of water in a test ask. Add a quantity of Methacrylic Acid and Ethyl Acrylate Copolymer, equivalent to 37.5 g of solids on the dried basis, while stirring by means of a magnetic stirrer. Close the ask, and continue stirring until the polymer has dissolved completely. Adjust the temperature to 20 ± 0.1°. Equip a rotational rheometer1 following Method II. The shear rate under the test condition is NLT 1 s−1 and NMT 100 s− 1. Validations demonstrate that equivalent viscosity value is also obtained using a rotational viscometer with a cylindrical spindle 1.9 cm in diameter and 6.5 cm high, attached to a shaft 0.3 cm in diameter.2 The spindle rotates at 30 rpm at an immersion depth of 8.15 cm (see Method I). Follow the instrument manufacturer's directions to measure the apparent viscosity.

Acceptance criteria: 100–200 mPa · s, for Methacrylic Acid and Ethyl Acrylate Copolymer with a range of 46.0%–50.6% for methacrylic acid units

5.2 Loss on Drying 〈731〉

Analysis: Dry at 110° for 6 h.

Acceptance criteria: NMT 5.0%

6 ADDITIONAL REQUIREMENTS

6.1 Packaging and Storage:

Preserve in tight containers, and store at controlled room temperature.

6.2 Labeling:

Label it to indicate the range of methacrylic acid units. The labeling also indicates the name and quantity of any added surface-active agent.

Change to read:

6.3 USP Reference Standards 〈11〉

USP Methacrylic Acid and Ethyl Acrylate Copolymer (1:1) RS (USP Methacrylic Acid Copolymer Type C RS) (ERR 1-Jul-2023)

1 A suitable rheometer is available from Physica Messtechnik GmbH as the Coaxial-Cylinder 27 or the Double-Gap-Cylinder 26.7, or any other equivalent rheometer.

2 A suitable spindle is available from Brookeld as an LV1 spindle, or the equivalent.