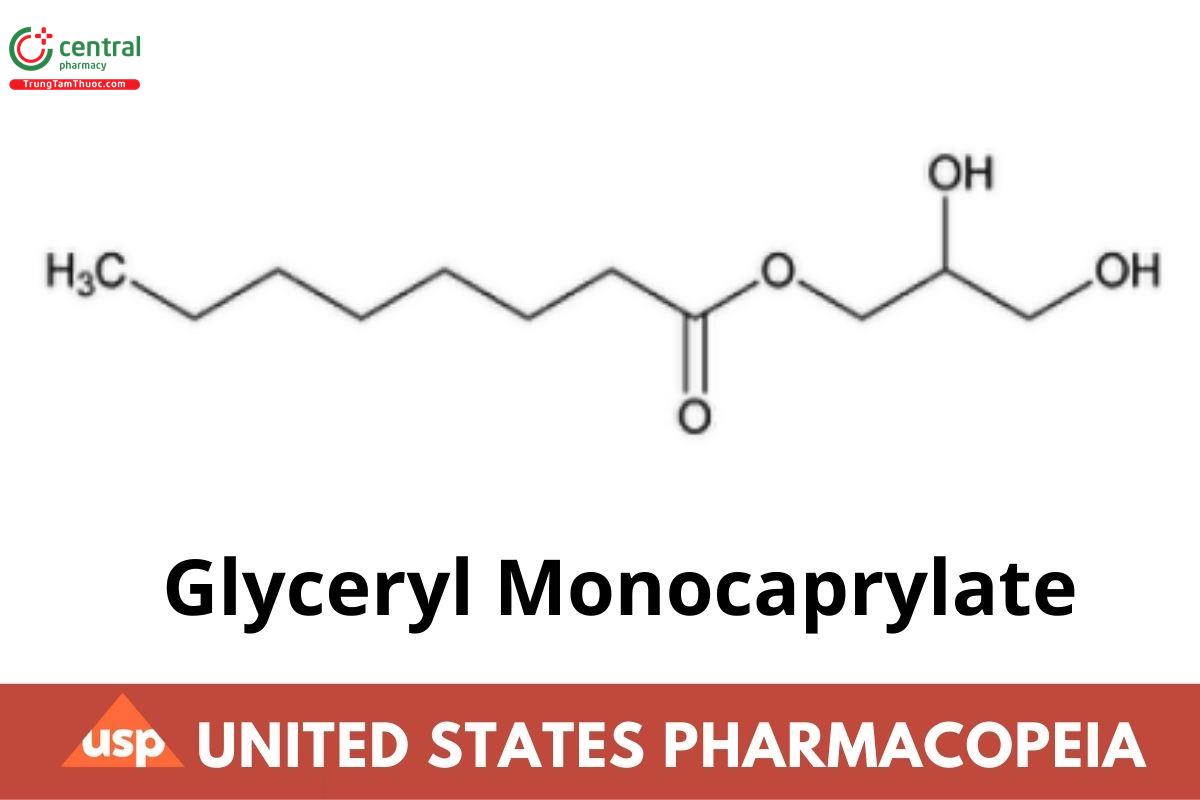

Glyceryl Monocaprylate

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

Add the following:

Any article currently titled Glyceryl Monocaprylate Type I will be socially titled Glyceryl Mono and Dicaprylate after May 1, 2025. Any article currently titled Glyceryl Monocaprylate Type II will be socially titled Glyceryl Monocaprylate after May 1, 2025. (NF 1-May-2020)

C11H22O4 218.29

Octanoic acid, monoester with 1,2,3-propanetriol;

Caprylic acid monoglyceride;

Glyceryl monooctanoate;

Monocapryl glyceride CAS RN®: 26402-26-6.

1 DEFINITION

Change to read:

Glyceryl Monocaprylate is a mixture of glyceryl monoesters, mainly mono-O-octanoylglycerol, containing variable quantities of diesters and triesters of fatty acids composed predominately of caprylic acid. The requirements for monoester, diester, and triester content are: Monoesters: NLT 75.1%; Diesters: NMT 24.9%; and Triesters: NMT 5.0%. (NF 1-May-2020)

2 IDENTIFICATION

A. Fatty Acid Composition

Boron trifluoride methanol solution: 140 mg/mL of boron trifluoride in methanol

Saturated sodium chloride solution: Mix 1 part sodium chloride with 2 parts water, shake from time to time, and allow to stand. Before use, decant the solution from any undissolved substance and filter, if necessary.

Standard solution 1: 1.0 mg/mL of USP Methyl Caproate RS, 1.0 mg/mL of USP Methyl Caprylate RS, and 2.0 mg/mL of USP Methyl Caprate RS in n-heptane

Standard solution 2: 0.1 mg/mL of USP Methyl Caproate RS, 0.1 mg/mL of USP Methyl Caprylate RS, and 0.2 mg/mL of USP Methyl Caprate RS in n-heptane, diluted from Standard solution 1

Standard solution 3: Prepare an ester mixture either by mixing a commercially available ester mixture with methyl caprylate and methyl caprate or by using USP Methyl Caproate RS, USP Methyl Caprylate RS, USP Methyl Caprate RS, USP Methyl Laurate RS, and USP Methyl Myristate RS. Dissolve a quantity of the prepared ester mixture containing methyl caproate, methyl caprylate, methyl caprate, methyl laurate, and methyl myristate in n-heptane to make a solution of about 9.0 mg/mL for methyl caprylate, 1.0 mg/mL for methyl caprate, and 0.05–0.1 mg/mL for each of the other methyl esters.

Sample solution: Transfer 100 mg of Glyceryl Monocaprylate to a 25-mL conical ask fitted with a suitable water-cooled reflux condenser and a magnetic stir bar. Add 2 mL of a 20-mg/mL solution of sodium hydroxide in methanol, mix, and reflux for about 30 min. Add 2 mL of Boron trifluoride methanol solution through the condenser, and reflux for about 30 min. Add 4 mL of n-heptane through the condenser and reflux for 5 min. Cool, remove the condenser, add about 10 mL of Saturated sodium chloride solution, shake, add a quantity of Saturated sodium chloride solution to bring the upper layer up to the neck of the ask, and allow the layers to separate. Collect 2 mL of the n-heptane layer (upper layer), wash with three quantities each of 2 mL of water, and dry the n-heptane phase over anhydrous sodium sulfate.

2.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: GC

Detector: Flame ionization

Column: 0.53-mm × 30-m capillary; bonded with a 1.0-µm layer of phase G16

Temperatures

Injection port: 250°

Detector: 250°

Column: See Table 1.

Table 1

Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

50 | 20 | 180 | — |

180 | 9 | 240 | 12 |

Carrier gas: Helium

Flow rate: 10 mL/min

Injection volume: 2 µL

Injection type: Split injection; split ratio, 4:1

2.2 System suitability

Samples: Standard solution 1 and Standard solution 2

[Note—The relative retention times for methyl caproate, methyl caprylate, and methyl caprate are about 0.7, 1.0, and 1.3, respectively.]

Suitability requirements

Resolution: NLT 4.0 between the methyl caprylate and methyl caprate peaks, Standard solution 1

Signal-to-noise ratio: NLT 10 for the methyl caproate peak, Standard solution 2

2.3 Analysis

Samples: Standard solution 3 and Sample solution

Measure the peak areas for the methyl esters of the fatty acids. Disregard any peaks with an area less than 0.05% of the total area and any peak due to the solvent. [Note—The relative retention times for several methyl esters are summarized in Table 2.]

Table 2

Carbon-Chain Length | Number of Double Bonds | Relative Retention Time |

6 | 0 | 0.7 |

8 | 0 | 1.0 |

10 | 0 | 1.3 |

12 | 0 | 1.6 |

14 | 0 | 1.9 |

Take the main component in Standard solution 3 as a reference component and calculate the calibration factor, F , for each fatty acid FA

methyl ester:

FFA = (FMC × PFA1 × AMC )/(PMC × A FA1)

FMC = factor for the main component, 1

PFA1 = percentage by weight of the fatty acid methyl ester in Standard solution 3

AMC = peak area of the main component from Standard solution 3

PMC = percentage by weight of the main component in Standard solution 3

A FA1= peak area of the fatty acid methyl ester from Standard solution 3

Calculate the percentage of the fatty acid methyl ester by weight in the portion of Glyceryl Monocaprylate taken:

Result = [(AFA2 × FFA )/AT ] × 100

AFA2 = peak area of the fatty acid methyl ester from the Sample solution

AT = sum of the peak areas of the fatty acid methyl esters from the Sample solution

Acceptance criteria: Glyceryl Monocaprylate exhibits the composition prole of fatty acids shown in Table 3.

Table 3

Carbon-Chain Length | Number of Double Bonds | Percentage (%, w/w) |

6 | 0 | ≤1.0 |

8 | 0 | ≥90.0 |

10 | 0 | ≤10.0 |

12 | 0 | ≤1.0 |

14 | 0 | ≤0.5 |

B. Glyceride Content: It meets the requirements of the test for Content of Monoglycerides, Diglycerides, and Triglycerides in the Assay. Change to read:

C. Fats and Fixed Oils 〈401〉, Procedures, Saponification Value: 245–272 (NF 1-May-2020)

3 ASSAY

Change to read:

Content of Monoglycerides, Diglycerides, and Triglycerides

System suitability solution: 20 mg/mL each of 1-monooctanoyl-rac-glycerol and 1-monodecanoyl-rac-glycerol in tetrahydrofuran Standard solution: 50 mg/mL of USP Glyceryl Monocaprylate RS in tetrahydrofuran

Sample solution: 50 mg/mL of Glyceryl Monocaprylate in tetrahydrofuran

3.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: GC

Detector: Flame ionization

Column: 0.32-mm × 10-m; bonded with a 0.1-µm layer of phase G27

Temperatures

Injection port: 350°

Detector: 370°

Column: See Table 4.

Table 4

Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

60 | — | 60 | 3 |

60 | 8 | 340 | 12 |

Carrier gas: Helium

Flow rate: 2.3 mL/min

Injection volume: 1 µL

Injection type: Split injection; split ratio, 50:1

System suitability

Samples: System suitability solution and Standard solution

[Note—The typical relative retention times for monoglycerides, diglycerides, and triglycerides are 1.0–1.2, 1.5–1.9, and 2.0–2.3, respectively, Standard solution.]

Suitability requirements

Resolution: NLT 5.0 between the 1-monooctanoyl-rac-glycerol and 1-monodecanoyl-rac-glycerol peaks, System suitability solution Analysis

Samples: Standard solution and Sample solution

Based on the chromatogram from the Standard solution, identify the peaks due to monoglycerides, diglycerides, and triglycerides in the Sample solution.

For the calculation of the contents of monoglycerides, diglycerides, and triglycerides, disregard the peaks with retention times less than those of the monoglycerides, which are due to impurities of the solvent and to the free fatty acids.

Calculate the percentage content of free fatty acids (CA ):

CA = [(IA × F × Mr1 )/Mr2 ] × 100

IA = acid value for Glyceryl Monocaprylate, determined from the test for Acid Value

F = conversion factor, 10−3 g/mg

Mr1 = molecular weight of caprylic acid, 144.21 g/mol

Mr2 = molecular weight of potassium hydroxide, 56.11 g/mol

Calculate the percentage of monoglycerides, diglycerides, or triglycerides in the portion of Glyceryl Monocaprylate taken:

Result = (rU /rT ) × [(100 − CA − CW − CG )/100] × 100

rU = peak response of the monoglycerides, diglycerides, or triglycerides from the Sample solution

rT = sum of all the glyceride peak responses from the Sample solution

CA = percentage of free fatty acids, determined above

CW = percentage of water, determined from the test for Water Determination

CG = percentage of free Glycerin, determined from the test for Limit of Free Glycerol

3.2 Acceptance criteria

Monoesters: NLT 75.1%

Diesters: NMT 24.9%

Triesters: NMT 5.0% (NF 1-May-2020)

4 IMPURITIES

4.1 Total Ash

Sample: 1.0 g

Analysis: Heat a silica or platinum crucible to redness for 30 min, allow to cool in a desiccator, and weigh. Evenly distribute the Sample in the crucible. Dry at 100°–105° for 1 h and ignite to constant weight in a mute furnace at 600 ± 25°, allowing the crucible to cool in a desiccator after each ignition. Flames should not be produced at any time during the procedure. If after prolonged ignition the ash still contains black particles, take up with hot water, pass through an ashless filter paper, and ignite the residue and the filter paper. Combine the filtrate with the ash, carefully evaporate to dryness, and ignite to constant mass.

Acceptance criteria: NMT 0.5%

4.2 Limit of Free Glycerol

Sample: 1.2 g

Periodic acetic acid solution: Dissolve 0.446 g of sodium periodate in 2.5 mL of a 25% (v/v) solution of sulfuric acid, and dilute with glacial acetic acid to 100.0 mL.

Potassium iodide solution: 75 mg/mL of potassium iodide

Blank: 25 mL of methylene chloride

Titrimetric system

(See Titrimetry 〈541〉.)

Mode: Residual titration

Titrant: 0.1 M sodium thiosulfate VS

Endpoint detection: Visual

Analysis: Dissolve the Sample in 25 mL of methylene chloride. Heat to about 50° and allow to cool. Add 100 mL of water. Shake and add 25 mL of Periodic acetic acid solution. Shake again and allow to stand for 30 min. Add 40 mL of Potassium iodide solution, and allow to stand for 1 min. Add 1 mL of starch TS and titrate the liberated iodine with Titrant until the aqueous phase becomes colorless. Perform a blank determination.

Calculate the percentage of free Glycerol in the portion of Glyceryl Monocaprylate taken:

Result = {[(VB − VS ) × N × E × F]/W} × 100

VB = volume of Titrant consumed in the Blank titration (mL)

VS = volume of Titrant consumed in the Sample titration (mL)

N = actual normality of the Titrant (mEq/mL)

E = equivalent factor for glycerol, 23 mg/mEq

F = conversion factor, 10−3 g/mg

W = weight of Glyceryl Monocaprylate taken for the titration (g)

Acceptance criteria: NMT 3.0%

5 SPECIFIC TESTS

Fats and Fixed Oils 〈401〉, Procedures, Acid Value: NMT 3.0

Fats and Fixed Oils 〈401〉, Procedures, Peroxide Value: NMT 1

Water Determination 〈921〉, Method I, Method Ia: NMT 1.0%

6 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in tight containers, and store at room temperature. Protect from moisture.

Delete the following:

Labeling: Label it to indicate the type (Type I or Type II). (NF 1-May-2020)

USP Reference Standards 〈11〉

USP Glyceryl Monocaprylate RS

USP Methyl Caprate RS

USP Methyl Caproate RS

USP Methyl Caprylate RS

USP Methyl Laurate RS

USP Methyl Myristate RS