Ethylene Glycol and Vinyl Alcohol Graft Copolymer - Definition, Identification, Impurities - USP 2025

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

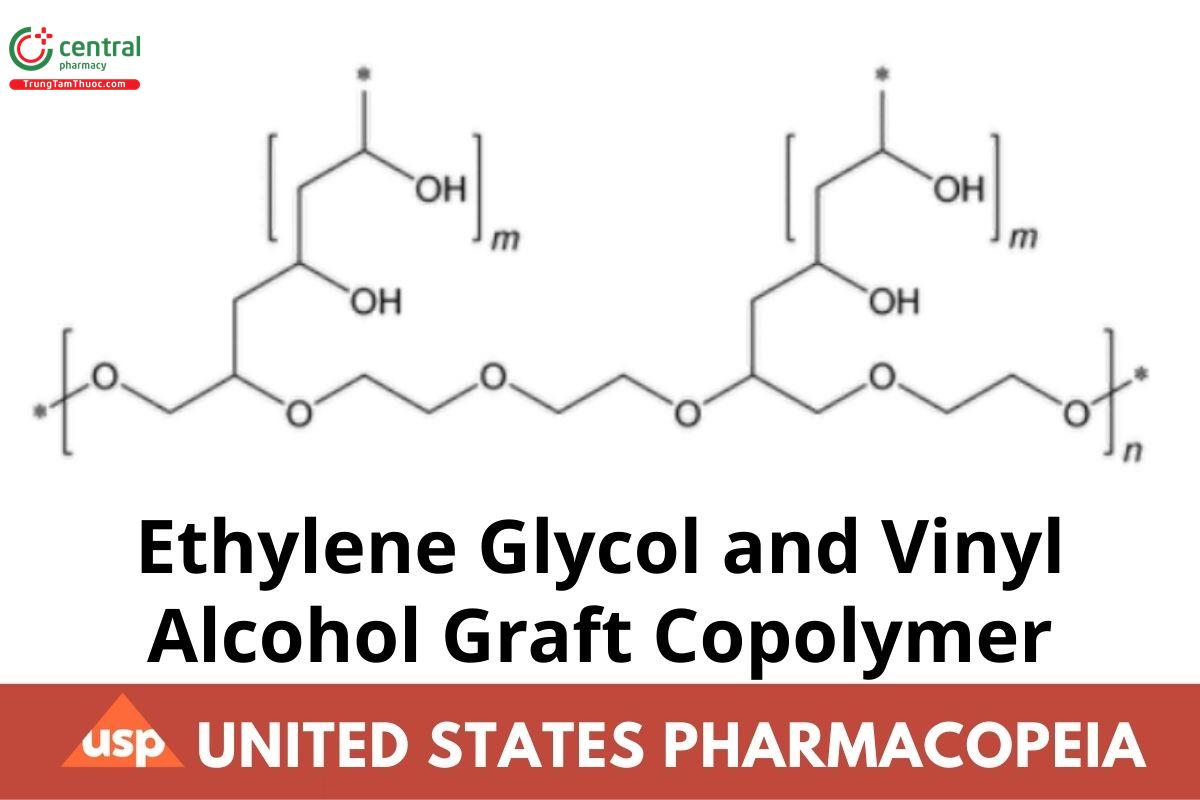

Ethylene Glycol and Vinyl Alcohol Graft Copolymer is a graft copolymer of ethylene glycol and vinyl alcohol. It consists of about 75% of vinyl alcohol (–CH₂CH(OH)–) units and 25% of ethylene glycol (–CH₂CH₂O–) units. The Copolymer is produced by using polyethylene glycol and vinyl acetate as starting materials. Polyethylene glycol forms the polymer backbone on which polyvinyl acetate is grafted. Hydrolysis of polyvinyl acetate side chains leads to formation of polyvinyl alcohol grafted chains. Ethylene Glycol and Vinyl Alcohol Graft Copolymer may contain glidant to improve flowability.

2 IDENTIFICATION

• Infrared Absorption

Sample: 200 mg of Ethylene Glycol and Vinyl Alcohol Graft Copolymer

Analysis: Dissolve the Sample in 5–10 mL of water. Spread 1 mL of this solution on a thallium bromoiodide window.¹ Totally moisten the surface area of the window. Dry the window at 110° for approximately 30 min, and allow the window to cool to room temperature.

Acceptance criteria: The IR absorption spectrum of Ethylene Glycol and Vinyl Alcohol Graft Copolymer exhibits maxima corresponding to the same wavelengths as those of a similar preparation of USP Ethylene Glycol and Vinyl Alcohol Graft Copolymer RS treated in the same manner.

3 IMPURITIES

3.1 Inorganic Impurities

• Residue on Ignition 〈281〉

Sample: 10.0 g

Acceptance criteria: NMT 3.0%

Change to read:

3.2 Organic Impurities

• Procedure 1: Ethylene Oxide and Dioxane

[Caution—Ethylene oxide is toxic and flammable. Prepare these solutions in a well-ventilated fume hood, using great care. Protect both hands and face by wearing polyethylene protective gloves and an appropriate face mask. Store all solutions in hermetic containers, and refrigerate at a temperature between 4° and 8°.]

[Note—Before using polyethylene glycol 200 in this test, remove any volatile components from it by placing 500 mL of polyethylene glycol 200 in a 1000-mL round-bottom flask, and attaching the flask to a rotary evaporator maintained at a temperature of 60° and under a vacuum of 10–20 mm Hg for 6 h.]

Acetaldehyde solution: 10 µg/mL of acetaldehyde.

[Note—Prepare the Acetaldehyde solution immediately before use.]

Ethylene oxide stock solution: Introduce 300 µL (corresponding to 250 mg) of gaseous ethylene oxide to the polyethylene glycol 200. Determine the absorbed mass of ethylene oxide via the weight of the solution before and after the absorption. Dilute the solution with the polyethylene glycol 200 to 100 g. This stock solution contains 2.5 mg/g of ethylene oxide.

[Note—Prepare this stock solution immediately before use, and store in a refrigerator after preparation.]

Ethylene oxide solution: 100 µg/g of ethylene oxide in polyethylene glycol 200 from Ethylene oxide stock solution. Transfer 5 g of 100 µg/g ethylene oxide in polyethylene glycol 200 to a 50-mL volumetric flask filled with 30 mL of water. Dilute with water to volume, and mix to obtain a solution containing 10 µg/mL of ethylene oxide.

[Note—Prepare this solution immediately before use, and use the solution directly after preparation.]

Dioxane solution: 500 µg/mL of dioxane

Standard solution A: Transfer 0.1 mL of Ethylene oxide solution to a 10-mL pressure headspace vial.

[Note—Other sizes, such as 22-mL, may be used, depending on the operating conditions; however, the same size must be used for Standard solution A, Standard solution B, and the Sample solution.]

Add 0.1 mL of Acetaldehyde solution and 0.1 mL of Dioxane solution, seal the vial, and mix.

Standard solution B: Transfer 1.0 g of Ethylene Glycol and Vinyl Alcohol Graft Copolymer to a 10-mL pressure headspace vial. Add 0.1 mL of Ethylene oxide solution, 0.1 mL of Dioxane solution, and 1.0 mL of N,N-dimethylacetamide, seal the vial, and mix.

Sample solution: Transfer 1.0 g of Ethylene Glycol and Vinyl Alcohol Graft Copolymer to a 10-mL pressure headspace vial. Add 1.0 mL of N,N-dimethylacetamide and 0.2 mL of water, seal the vial, and mix.

3.3 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

[Note—Use a headspace apparatus that automatically transfers a measured amount of headspace.]

Mode: GC

Detector: Flame ionization

Detector temperature: 250°

Column: 0.25-mm × 30-m glass or quartz capillary column; 1.0-µm layer of phase G1

Column temperature: See the temperature program table below.

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

| 50 | _ | 50 | 5 |

| 50 | 5 | 180 | _ |

| 180 | 30 | 230 | 5 |

Carrier gas: Helium

Flow rate: 0.8 mL/min

Injection size: 1 mL (the gaseous headspace)

Injection type: Split ratio 20:1

Injection port temperature: 250°

3.4 Headspace sampler

Equilibration time: 45 min

Equilibration temperature

Standard solution A: 70°

Standard solution B: 90°

Sample solution: 90°

Transfer line temperature: 150°

Pressurization time: 1 min

Final headspace pressure: 0.7 bar

Injection time: 12 s

3.5 System suitability

Sample: Standard solution A

[Note—The relative retention times for acetaldehyde and ethylene oxide are 0.94 and 1.0, respectively.]

Suitability requirements

Resolution: NLT 1.5 between acetaldehyde and ethylene oxide

Signal-to-noise: NLT 5 determined from the dioxane peak

Relative standard deviation: NMT 15%

3.6 Analysis

Samples: Standard solution B and Sample solution

Calculate the content of ethylene oxide, in ppm, in the portion of Ethylene Glycol and Vinyl Alcohol Graft Copolymer taken:

Result = A × rₑᵤ /[(rₛᵤ × Wₛ) − (rᵤₛ × Wᵤ)]

A = quantity of ethylene oxide added to Standard solution B (µg)

rᵤ = ethylene oxide peak response from the Sample solution

rₛ = ethylene oxide peak response from Standard solution B

Wᵤ = weight of Ethylene Glycol and Vinyl Alcohol Graft Copolymer taken to prepare the Sample solution (g)

Wₛ = weight of Ethylene Glycol and Vinyl Alcohol Graft Copolymer taken to prepare Standard solution B (g)

Calculate the content of dioxane, in ppm, in the portion of Ethylene Glycol and Vinyl Alcohol Graft Copolymer taken:

Result = A × rᵤ /[(rₛ × Wₛ) − (rᵤ × Wᵤ)]

A = quantity of dioxane added to Standard solution B (µg)

rᵤ = dioxane peak response from the Sample solution

rₛ = dioxane peak response from Standard solution B

Wᵤ = weight of Ethylene Glycol and Vinyl Alcohol Graft Copolymer taken to prepare the Sample solution (g)

Wₛ = weight of Ethylene Glycol and Vinyl Alcohol Graft Copolymer taken to prepare Standard solution B (g)

Acceptance criteria: NMT 1 ppm of ethylene oxide; NMT 10 ppm of dioxane

• Procedure 2: Vinyl Acetate

Solution A: Acetonitrile, methanol, and water (5:5:90)

Solution B: Acetonitrile, methanol, and water (45:5:50)

Mobile phase: See the gradient table below.

| Time (min) | Solution A (%) | Solution B (%) |

| 0 | 100 | 0 |

| 2 | 100 | 0 |

| 40 | 85 | 15 |

| 42 | 0 | 100 |

| 48 | 0 | 100 |

| 51 | 100 | 0 |

System suitability solution: Transfer 50 mg of vinyl acetate and 50 mg of 1-vinylpyrrolidin-2-one to a 50-mL volumetric flask, add 10 mL of methanol, and sonicate or gently shake the flask to dissolve the materials. Dilute with Solution A to volume. Dilute 10 mL of this solution with Solution A to 100 mL. Dilute 5 mL of this solution with Solution A to 100 mL. The System suitability solution contains about 5 µg/mL each of vinyl acetate and 1-vinylpyrrolidin-2-one.

Standard solution: Transfer 50 mg of vinyl acetate to a 100-mL volumetric flask, dissolve in and dilute with methanol to volume, and mix well. Dilute 5.0 mL of the solution with Solution A to 100 mL. Dilute 10.0 mL of this solution with Solution A to 100 mL. The Standard solution contains about 2.5 µg/mL of vinyl acetate.

[Note—This solution should be analyzed within 1 h when stored at room temperature.]

Sample solution: Transfer 250 mg of Ethylene Glycol and Vinyl Alcohol Graft Copolymer to a 10-mL volumetric flask, and add 1–2 mL of methanol, using an ultrasonic bath if necessary. After cooling to ambient temperature, dilute with water to volume, and mix. Pass through a ▲0.2-µm▲ (ERR 1-Jun-2018) membrane filter.

[Note—This solution should be analyzed within 1 h when stored at room temperature.]

3.7 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 205 nm

Column: 4.0-mm × 25-cm analytical column; 5-µm packing L1. A 4.0-mm × 3-cm pre-column; 5-µm packing L1 may be used if a matrix effect is observed.

[Note—The matrix effect may result in poor reproducibility of the retention times and of the peak shapes.]

Column temperature: 30°

Flow rate: 1 mL/min

Injection size: 10 µL

3.8 System suitability

Sample: System suitability solution

[Note—The relative retention times for vinyl acetate and 1-vinylpyrrolidin-2-one are 1.0 and 1.4, respectively.]

Suitability requirements

Resolution: NLT 5.0 between vinyl acetate and 1-vinylpyrrolidin-2-one

Relative standard deviation: NMT 5.0% determined from the 1-vinylpyrrolidin-2-one peak

3.9 Analysis

Samples: Standard solution and Sample solution

Acceptance criteria: The response of the vinyl acetate peak from the Sample solution is NMT that of the vinyl acetate peak from the Standard solution, corresponding to NMT 100 ppm of vinyl acetate.

• Procedure 3: Acetic Acid/Acetate

Mobile phase: 5 mM sulfuric acid

Standard solution: 0.3 mg/mL for each of acetic acid and citric acid in Mobile phase

Sample solution: 20 mg/mL of Ethylene Glycol and Vinyl Alcohol Copolymer

3.10 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 205 nm

Column: 4.6-mm × 25-cm; 5-µm packing L1

Column clean: After each injection, rinse the column with a mixture of equal volumes of Mobile phase and acetonitrile.

Column temperature: Ambient

Flow rate: 1 mL/min

Injection size: 20 µL

System suitability

Sample: Standard solution

[Note—The relative retention times for acetic acid and citric acid are 1.0 and 1.3, respectively.]

Suitability requirements

Resolution: NLT 2.0 between acetic acid and citric acid

Relative standard deviation: NMT 5.0% determined from the acetic acid peak

3.11 Analysis

Samples: Standard solution and Sample solution

Acceptance criteria: The response of the acetic acid peak from the Sample solution is NMT that of the acetic acid peak from the Standard solution, corresponding to NMT 1.5% of acetic acid.

4 SPECIFIC TESTS

• Fats and Fixed Oils, Ester Value 〈401〉: 10–75

• Loss on Drying 〈731〉: Dry 1.0 g of Ethylene Glycol and Vinyl Alcohol Graft Copolymer in a vacuum at 140° for 1 h: it loses NMT 5.0% of its weight.

• pH 〈791〉: 5.0–8.0, in a solution of 20% (w/w) in carbon dioxide-free water

• Viscosity—Rotational Methods 〈912〉: After determining the Loss on Drying, weigh a quantity of undried Ethylene Glycol and Vinyl Alcohol Graft Copolymer, equivalent to 100.0 g on the dried basis. Transfer the sample to a short form, 600-mL beaker (internal diameter about 80 mm and height 120 mm), and add water to make the mixture weigh 500 g. Ensure a homogeneous solution by gently stirring at room temperature for 48 h. Afterwards allow the container to stand for 24 h to let the entrapped air dissipate.

[Note—Ensure that the concentration of this solution is 20% (w/w).]

Determine the viscosity of this solution at 23 ± 0.1° using a suitable rotational viscometer with a spindle having a cylinder 4.7 cm in diameter and 0.2 cm high attached to a shaft 0.3 cm in diameter, the distance from the top of the cylinder to the lower tip of the shaft being 2.7 cm, and the immersion depth being 4.9 cm.² Operate the viscometer at 100 rpm. Follow the instrument manufacturer's directions to measure the apparent viscosity.

Acceptance criteria: 25–250 mPa·s

5 ADDITIONAL REQUIREMENTS

• Packaging and Storage: Preserve in well-closed containers, and store at a temperature below 25°.

• Labeling: Label it to indicate the viscosity, giving the viscosity measurement parameters, concentration of the solution, and the type of equipment used. The labeling also indicates the name and quantity of any added glidant.

• USP Reference Standards 〈11〉

USP Ethylene Glycol and Vinyl Alcohol Graft Copolymer RS