Emulsifying Wax

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

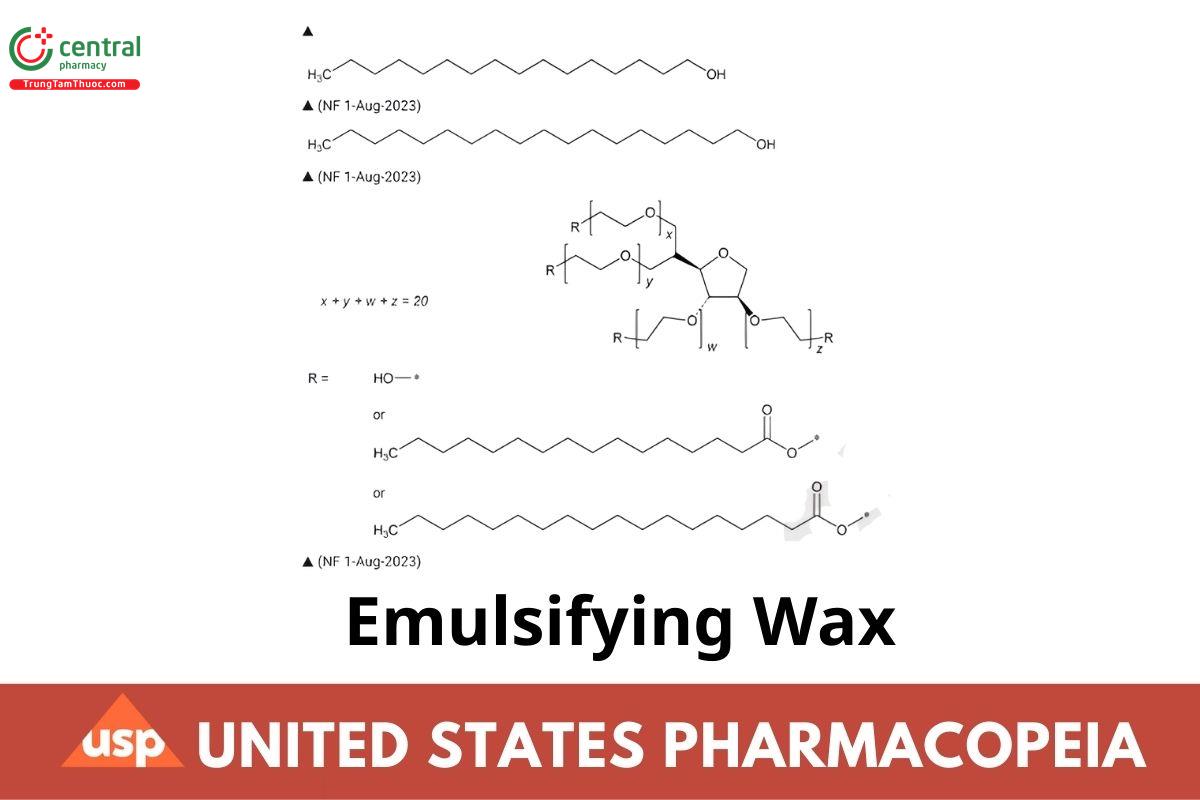

Emulsifying Wax is a waxy solid prepared from cetostearyl alcohol containing a polyoxyethylene derivative of a fatty acid ester of sorbitan.

Add the following:

2 IDENTIFICATION

A. Spectroscopic Identification Tests 〈197〉, Infrared Spectroscopy: 197A or 197F

Sample: Use a thin

lm of melted test specimen when performing 197F.

Acceptance criteria: Meets the requirements

B. It meets the requirements in Specific Tests for Fats and Fixed Oils 〈401〉, Procedures, Fatty Acid Composition. (NF 1-Aug-2023)

3 SPECIFIC TESTS

Melting Range or Temperature 〈741〉

Sample: Emulsifying Wax

Analysis: Melt a quantity of the Sample slowly, while stirring, until it reaches a temperature of 90°–92°. Remove the source of the heat, and allow the molten substance to cool to a temperature of 8°–10° above the expected melting point. Chill the bulb of a suitable thermometer (see General Notices, 6.80.30. Temperature Reading Devices) to 5°, wipe it dry, and while it is still cold, dip it into the molten substance so that the bulb is completely covered. Withdraw it immediately, and hold it vertically away from the heat until the surface dulls. Fix the thermometer securely in a test tube so that the lower point is 15 mm from the bottom of the test tube. Place the test tube in a water bath at 10°–15°, and allow it to remain at that temperature for 30 min. Raise the temperature of the bath at the rate of 2°/min to 30°, then change to a rate of 1°/min, and note the temperature at which the first drop of melted substance leaves the thermometer. Repeat the determination twice on a freshly melted portion of the sample substance. If the variation of three determinations is less than 1°, take the average of the three as the melting point. Otherwise, make two additional determinations, and take the average of the five.

Acceptance criteria: 50°–54°

Add the following:

Fats and Fixed Oils 〈401〉, Procedures, Fatty Acid Composition

Analysis

Calculate the percentage of each fatty acid methyl ester component in the test specimen:

Result = (rU/rT) × 100

rU = peak area of each individual fatty acid ester component from the Test solution (see Table 1)

rT = sum of the peak areas of the fatty acid methyl esters (methyl myristate, methyl palmitate, methyl stearate) in the chromatogram from the Test solution

Table 1

| Component | Relative Retention Time |

|---|---|

| Methyl Myristate | 0.9 |

| Methyl Palmitate | 1.0 |

| Methyl Stearate | 1.1 |

Acceptance criteria

For stearic acid: 40.0%–60.0%

Sum of stearic acid and palmitic acid: NLT 90.0% (NF 1-Aug-2023)

Fats and Fixed Oils 〈401〉, Procedures, Hydroxyl Value: 178–192

Fats and Fixed Oils 〈401〉, Procedures, Iodine Value: NMT 3.5

Fats and Fixed Oils 〈401〉, Procedures, Saponification Value: NMT 14

pH 〈791〉

Sample dispersion: Heat 3 g of Emulsifying Wax in 100 mL of water to 55°, with stirring, followed by cooling to 25°.

Acceptance criteria: 5.5–7.0

4 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in well-closed containers.

Add the following:

USP Reference Standards 〈11〉

USP Emulsifying Wax RS (NF 1-Aug-2023)