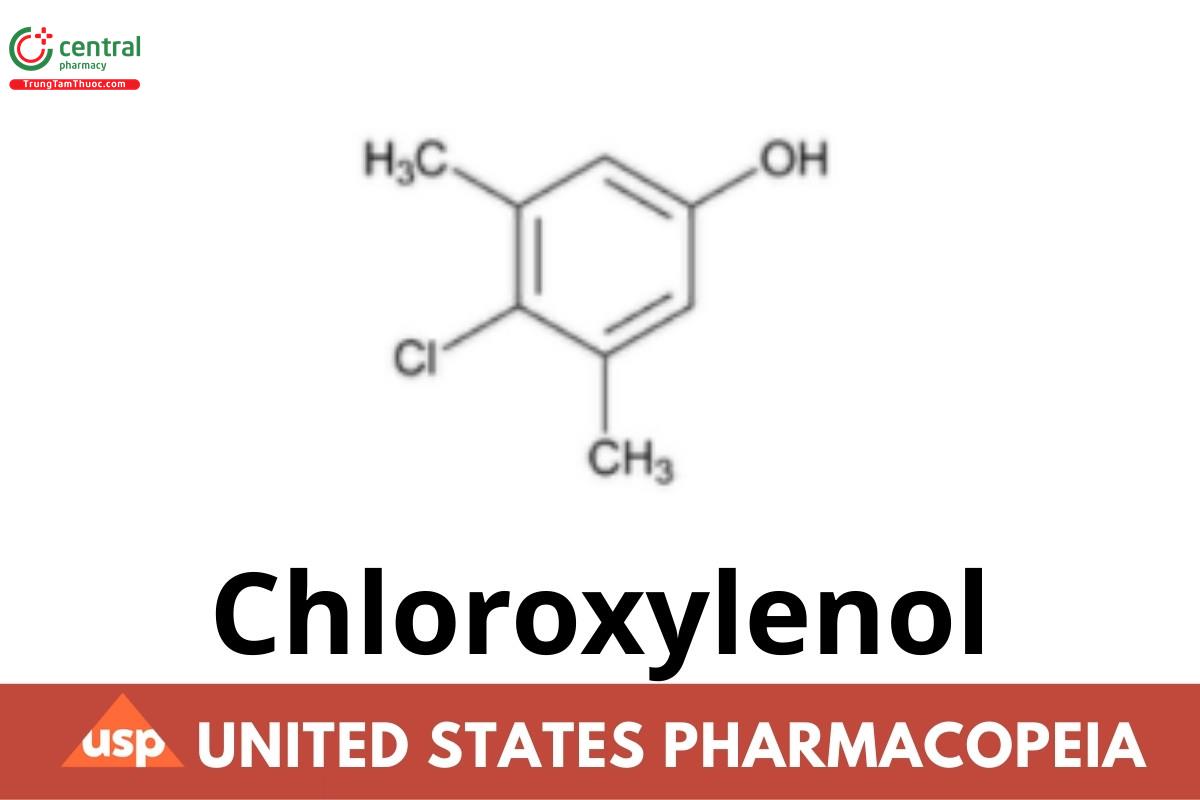

Chloroxylenol

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

Chloroxylenol contains NLT 98.5% of chloroxylenol (C8H9ClO).

2 IDENTIFICATION

A. SPECTROSCOPIC IDENTIFICATION TESTS 〈197〉 , Infrared Spectroscopy : 197K

B. The retention time of the major peak of the Sample solution corresponds to that of the Standard solution, as obtained in the Assay.

3 ASSAY

3.1 PROCEDURE

Internal standard solution: 4 mg/mL of USP Parachlorophenol RS in toluene

Standard solution: 1 mg/mL of USP Chloroxylenol RS prepared as follows. Transfer 10 mg of USP Chloroxylenol RS to a 10.0-mL volumetric flask, add 2.0 mL of the Internal standard solution, and dilute with toluene to volume.

Sample solution: 1 mg/mL of Chloroxylenol prepared as follows. Transfer 10 mg of Chloroxylenol to a 10.0 mL volumetric flask, add 2.0 mL of the Internal standard solution, and dilute with toluene to volume.

3.1.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.) Mode: GC

Detector: Flame ionization

Column: 0.32-mm × 30-m; coated with a 0.50-µm film of phase G42 Temperatures

Injection port: 250°

Detector: 250° Column: See Table 1.

Table 1

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

| 105 | 0 | 105 | 1 |

| 105 | 6 | 190 | 8 |

Carrier gas: Helium Flow rate: 2.4 mL/min Injection volume: 2 µL

Split ratio: 25:1 Run time: 23 min

3.1.2 System suitability

Sample: Standard solution

Suitability requirements

Resolution: NLT 5.0 between the parachlorophenol peak and the chloroxylenol peak Tailing factor: NMT 1.5 for the chloroxylenol peak

Relative standard deviation: NMT 1.5%

3.1.3 Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of chloroxylenol (C8H9ClO) in the portion of Chloroxylenol taken:

Result = (Ru/Rs) × (Cs/Cu) × 100

Ru = peak area ratio of the chloroxylenol peak to the parachlorophenol peak from the Sample solution

Rs = peak area ratio of the chloroxylenol peak to the parachlorophenol peak from the Standard solution

Cs = concentration of USP Chloroxylenol RS in the Standard solution (mg/mL)

Cu = concentration of Chloroxylenol in the Sample solution (mg/mL)

Acceptance criteria: NLT 98.5%

4 IMPURITIES

4.1 RESIDUE ON IGNITION 〈281〉: NMT 0.1%

Change to read:

4.2 IRON 〈241〉

Procedures, Procedure 1 (CN 1-JUN-2023)

Sample: 0.10 g

Analysis: Transfer the Sample to a suitable crucible, add 5 drops of sulfuric acid, and ignite at a low heat until thoroughly ashed. Add 10 drops of sulfuric acid to the carbonized mass, and heat cautiously until white fumes are no longer evolved. Ignite, preferably in a muffle furnace, at 500°–600°, until the carbon is completely burned off. Cool, add 4 mL of 6 N hydrochloric acid, cover, digest on a steam bath for 15 min, uncover, and slowly evaporate on a steam bath to dryness. Moisten the residue with 1 drop of hydrochloric acid, add 10 mL of hot water, and digest for 2 min. Dilute with water to 25 mL. Filter, if necessary. Rinse the crucible and the filter with 10 mL of water, combining the filtrate and rinsing in a 50-mL color-comparison tube; add 2 mL of hydrochloric acid; dilute with water to 47 mL; and mix.

Acceptance criteria: NMT 0.01%

4.3 LIMIT OF TETRACHLOROETHYLENE

Internal standard stock solution: 20 µL/mL of 1-butanol in methanol

Internal standard solution: 2 µL/mL of 1-butanol in methanol from Internal standard stock solution Tetrachloroethylene standard stock solution: 20 µL/mL of tetrachloroethylene in methanol

Tetrachloroethylene standard solution: 2 µL/mL of tetrachloroethylene in methanol from Tetrachloroethylene standard stock solution Standard solution: 0.4 µL/mL each of 1-butanol and tetrachloroethylene in methanol from Internal standard solution and Tetrachloroethylene standard solution, respectively, prepared as follows. Combine 5 mL each of Internal standard solution and Tetrachloroethylene standard solution in a 25-mL volumetric flask, dilute with methanol to volume, and mix.

Sample solution: 160 mg/mL of chloroxylenol and 0.4 µL/mL of 1-butanol in methanol prepared as follows. Weigh 4 g of chloroxylenol in a 25-mL volumetric flask, combine with 5 mL of Internal standard solution, and dilute with methanol to volume.

4.3.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.) Mode: GC

Detector: Flame ionization

Column: 0.53-mm × 30-m; 1.0-µm film of phase G14 or G16 Carrier gas: Hydrogen

Temperatures Injector: 240°

Detector: 240°

Column: See Table 2.

Table 2

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

| 70 | 0 | 70 | 2 |

| 70 | 35 | 210 | 5 |

Flow rate: 12.8 mL/min Injection volume: 0.5 µL Split ratio: 20:1

4.3.2 System suitability

Sample: Standard solution

[NOTE—The relative retention times for tetrachloroethylene and 1-butanol are about 1.0 and 1.9, respectively.]

Suitability requirements

Resolution: NLT 1.5 between tetrachloroethylene and the solvent front of methanol Tailing factor: NM T 1.2 for the tetrachloroethylene and 1-butanol peaks

Relative standard deviation: NMT 8.0% for the ratio of the 1-butanol to the tetrachloroethylene peak

4.3.3 Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of tetrachloroethylene in the portion of Chloroxylenol taken by comparing the peak response ratio of tetrachloroethylene to the internal standard from the Standard solution to that of the peak response ratio of tetrachloroethylene to the internal standard from the Sample solution:

Result = (Ru/Rs) × (Cs/Cu) × d × F × 100

Ru = peak response ratio of tetrachloroethylene to 1-butanol from the Sample solution

Rs = peak response ratio of tetrachloroethylene to 1-butanol from the Standard solution

Cs = concentration of tetrachloroethylene in the Standard solution (mL/mL)

Cu = concentration of Chloroxylenol in the Sample solution (mg/mL)

d = density of tetrachloroethylene, 1.623 g/mL

F = conversion factor, 1 mg/0.001 g

Acceptance criteria: NMT 0.4% of tetrachloroethylene

4.4 ORGANIC IMPURITIES

Standard solution: 0.02 mg/mL each of 3,5-dimethylphenol and USP Chloroxylenol Related Compound A RS in toluene Sample solution: 10.0 mg/mL of Chloroxylenol in toluene

Chromatographic system: Proceed as directed in the Assay.

4.4.1 System suitability

Sample: Standard solution

[NOTE—For relative retention times, see Table 3.] Suitability requirements

Resolution: NLT 8 between 3,5-dimethylphenol and chloroxylenol related compound A Relative standard deviation: NMT 3%

4.4.2 Analysis

Samples: Standard solution and Sample solution

Calculate the percentages of 3,5-dimethylphenol (C8H10O) and chloroxylenol related compound A (C8H9ClO) in the portion of Chloroxylenol taken:

Result = (ru/rs) × (Cs/Cu) × 100

ru = peak response of the appropriate analyte from the Sample solution

rs = peak response of the 3,5-dimethylphenol or chloroxylenol related compound A from the Standard solution

Cs = concentration of 3,5-dimethylphenol or USP Chloroxylenol Related Compound A RS in the Standard solution (mg/mL)

Cu = concentration of the Sample solution (mg/mL)

Calculate the percentage of each unspecified impurity in the portion of Chloroxylenol taken:

Result = (rU/rT) × 100

rU = peak response of each unspecified impurity from the Sample solution

rT = sum of all the peak responses

Acceptance criteria: See Table 3.

Table 3

| Name | Relative Retention Time | Acceptance Criteria, NMT (%) |

| 3,5-Dimethylphenol | 0.58 | 0.2 |

| Chloroxylenol related compound A | 0.64 | 0.2 |

| Chloroxylenol | 1.0 | — |

| Any individual impurity | — | 0.5 |

| Total impurities | — | 1.5 |

5 SPECIFIC TESTS

WATER DETERMINATION, Method I〈921〉: NMT 0.5%

6 ADDITIONAL REQUIREMENTS

PACKAGING AND STORAGE: Preserve in well-closed containers.

USP REFERENCE STANDARDS 〈11〉

USP Chloroxylenol RS

USP Chloroxylenol Related Compound A RS

2-Chloro-3,5-dimethylphenol.

USP Parachlorophenol RS