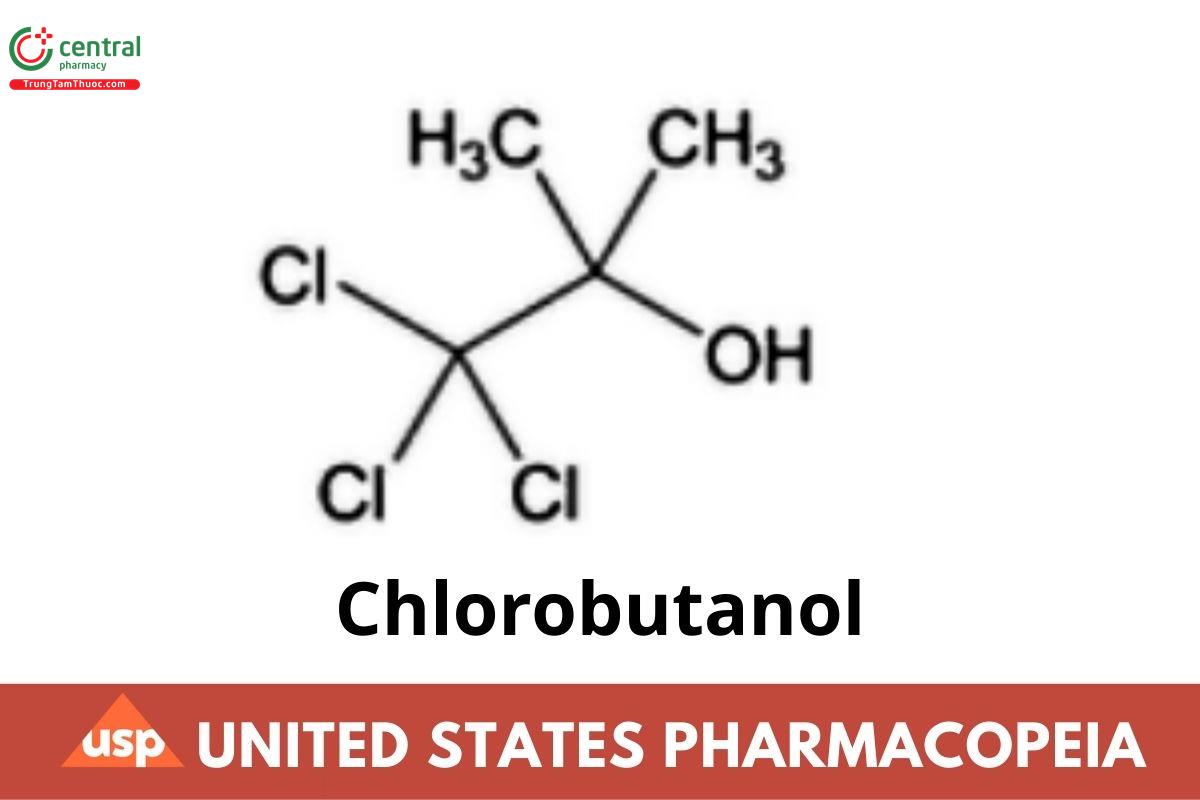

Chlorobutanol

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

C4H7Cl3O 177.46

C4H7Cl3O · ½H2O 186.46

2-Propanol, 1,1,1-trichloro-2-methyl-;

1,1,1-Trichloro-2-methyl-2-propanol CAS RN®: 57-15-8.

Hemihydrate CAS RN®: 6001-64-5.

1 DEFINITION

Chlorobutanol is anhydrous or contains NMT one-half molecule of water of hydration. It contains NLT 98.0% and NMT 100.5% of chlorobutanol (C4H7Cl3O), calculated on the anhydrous basis.

2 IDENTIFICATION

Change to read:

A. Spectroscopic Identification Tests 〈197〉, Infrared Spectroscopy: 197K (CN 1-May-2020)

B. The retention time of the chlorobutanol peak of the Sample solution corresponds to that of the Standard solution, as obtained in the Assay.

3 ASSAY

Procedure

Standard solution: 10.0 mg/mL of USP Chlorobutanol RS and 15.0 mg/mL of 2,2,2-trichloroethanol (internal standard) in n-hexane Sample solution: 10.0 mg/mL of Chlorobutanol and 15.0 mg/mL of 2,2,2-trichloroethanol (internal standard) in n-hexane

3.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: GC

Detector: Flame ionization

Column: 0.32-mm × 30-m fused silica; coated with a 0.25-µm layer of stationary phase G16

Temperatures

Injection port: 260°

Detector: 280°

Column: 135°

Carrier gas: Helium

Flow rate: 1.0 mL/min

Injection volume: 1 µL

Injection type: Split injection, split ratio 10:1

Run time: 12 min

3.2 System suitability

Sample: Standard solution

[Note—The relative retention times for chlorobutanol and 2,2,2-trichloroethanol are 1.0 and 1.3, respectively.] Suitability requirements

Resolution: NLT 5 between the chlorobutanol and 2,2,2-trichloroethanol peaks

Tailing factor: NMT 1.5 for the chlorobutanol peak

Relative standard deviation: NMT 0.3% for peak area ratio of chlorobutanol to the internal standard

3.3 Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of chlorobutanol (C4H7Cl3O) in the portion of Chlorobutanol taken:

Result = (RU /RS ) × (CS /CU ) × P × 100

RU = peak area ratio of chlorobutanol to the internal standard from the Sample solution

RS = peak area ratio of chlorobutanol to the internal standard from the Standard solution

CS = concentration of USP Chlorobutanol RS in the Standard solution (mg/mL)

CU = concentration of Chlorobutanol in the Sample solution (mg/mL)

P = labeled purity of USP Chlorobutanol RS

Acceptance criteria: 98.0%–100.5% on the anhydrous basis

4 IMPURITIES

4.1 Chloride

Control solution: 0.50 mL of 0.020 N hydrochloric acid in a mixture of 25 mL of diluted alcohol and 1 mL of nitric acid Sample solution: 0.50 g of Chlorobutanol in a mixture of 25 mL of diluted alcohol and 1 mL of nitric acid

Analysis: To the Control solution and Sample solution add 2 mL of silver nitrate TS.

Acceptance criteria: 0.07%; any turbidity produced in the Sample solution is NMT that produced in the Control solution.

5 SPECIFIC TESTS

Water Determination 〈921〉, Method I: NMT 1.0% (anhydrous form) and NMT 6.0% (hydrous form)

Reaction

Sample: 0.5 g

Analysis: Shake the Sample thoroughly with 25 mL of water.

Acceptance criteria: The water remains neutral to litmus.

Bacterial Endotoxins Test 〈85〉: If labeled for use in preparing parenteral dosage forms, it also meets the following requirements. The level of bacterial endotoxins is such that the requirement in the relevant dosage form monograph(s) in which Chlorobutanol is used can be met. Where

the label states that Chlorobutanol must be subjected to further processing during the preparation of injectable dosage forms, the level of bacterial endotoxins is such that the requirement in the relevant dosage form monograph(s) in which Chlorobutanol is used can be met.

6 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in tight containers.

Labeling: Label it to indicate whether it is anhydrous or hydrous. Where Chlorobutanol is intended for use in the manufacture of injectable dosage forms, it is so labeled. Where Chlorobutanol must be subjected to further processing during the preparation of injectable dosage forms to ensure acceptable levels of bacterial endotoxins, it is so labeled.

USP Reference Standards 〈11〉

USP Chlorobutanol RS