Carbomer 941

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

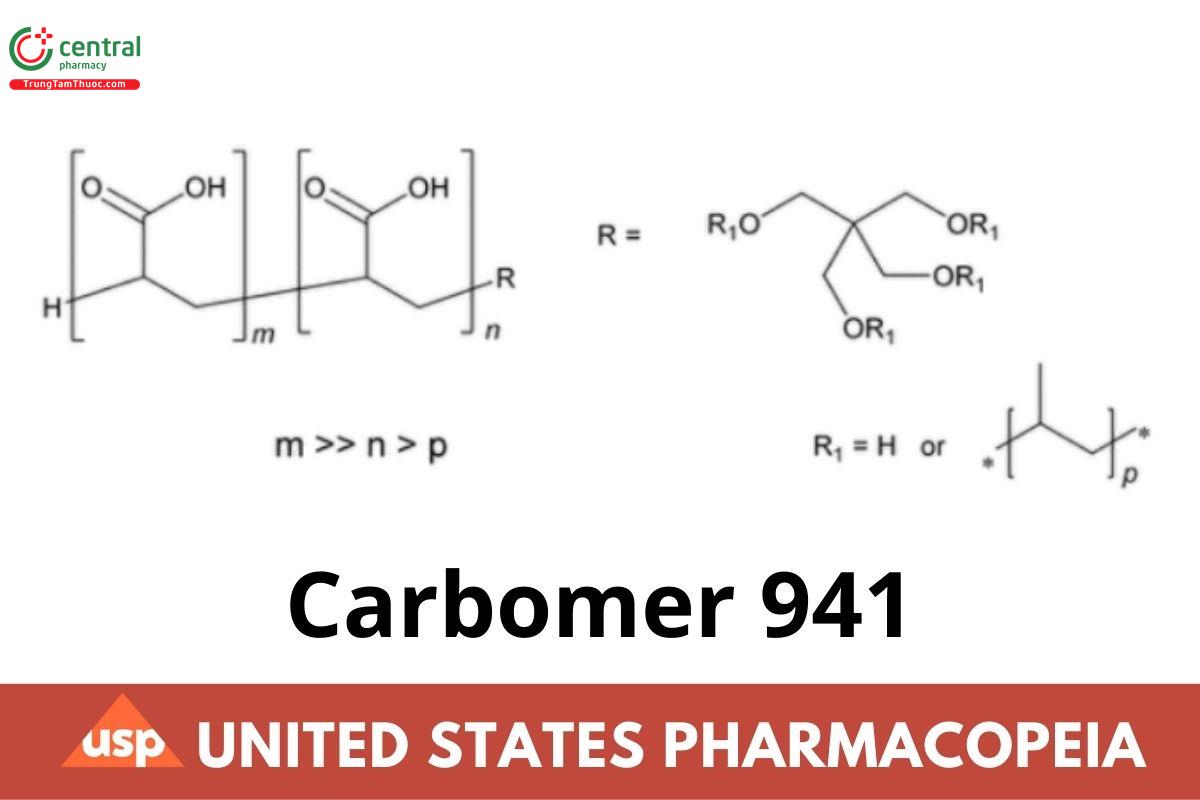

1 DEFINITION

Carbomer 941 is a high molecular weight polymer of Acrylic acid cross-linked with allyl ethers of pentaerythritol. Carbomer 941 (NF 1-May 2022) contains NLT 56.0% and NMT 68.0% of carboxylic acid (–COOH) groups calculated on the dried basis. (NF 1-May-2022) The viscosity a neutralized 0.5% aqueous dispersion of Carbomer 941 is between 4000 and 11,000 mPa · s.

2 IDENTIFICATION

Add the following:

A. Spectroscopic Identification Tests 〈197〉, Infrared Spectroscopy: 197A or 197K. The IR absorption spectrum exhibits maxima only at the same wavelengths as those of a similar preparation of USP Carbomer Homopolymer RS, treated in the same manner. [Note—If peak shifting occurs during testing using the method found in 197A causing the test to fail, follow the method found in 197K.] (NF 1-May-2022)

Change to read:

B. (NF 1-May-2022)

Sample dispersion: 10 mg/mL

Analysis 1: To one portion of the Sample dispersion add thymol blue TS.

Acceptance criteria 1: An orange color is produced.

Analysis 2: To another portion of the Sample dispersion add cresol red TS.

Acceptance criteria 2: A yellow color is produced.

Change to read:

C. (NF 1-May-2022)

Sample dispersion: 10 mg/mL

Analysis: Adjust the Sample dispersion with 1 N sodium hydroxide to a pH of 7.5, or follow the procedure described in the test for Viscosity— Rotational Methods until neutralization is complete and the nal pH of 7.3–7.8 is reached. (NF 1-May-2022)

Acceptance criteria: A very viscous gel is produced.

3 ASSAY

Change to read:

Carboxylic Acid Content

Sample: 400 mg, previously dried

Titrimetric system

(See Titrimetry 〈541〉.)

Mode: Direct titration

Electrode: Calomel–glass or silver/silver chloride (NF 1-May-2022) Titrant: 0.25 N sodium hydroxide VS

Endpoint detection: Potentiometric

Analysis: Slowly add the Sample to 400 mL of water in an 800–1000-mL (NF 1-May-2022) beaker, while stirring continuously at about 1000 ± 10 (NF 1-May-2022) rpm, with the stirrer shaft set at the side of the beaker at an angle of 60° and with the propeller positioned near the bottom of the beaker. Continue stirring for 15 min. Turn off the stirrer and remove the stirrer shaft with the propeller from the beaker. Scrape any sample from the beaker walls, stirrer shaft, and propeller blades with a spatula or rubber policeman into the dispersion. Allow the polymer dispersion to stand for 30 min. Transfer the beaker to a magnetic stirring device. Place an approximately 7.62-cm stirring bar into the solution, and adjust the mixer speed to obtain moderate mixing. Add 1 g of potassium chloride, (NF 1-May-2022) and titrate potentiometrically with Titrant. After each addition of Titrant allow 1 min for mixing before recording the pH.

Calculate the carboxylic acid content as a percentage of carboxylic acid groups in the portion of Carbomer 941 taken: (NF 1-May-2022)

Result = [(V × NA (NF 1-May-2022) /W) × F] × 100

V = Titrant volume consumed (mL)

NA (NF 1-May-2022) /W) = actual normality of the Titrant (mEq/mL)

W = Sample weight (mg)

F = equivalency factor for the carboxylic acid (–COOH) group, 45.02 mg/mEq (NF 1-May-2022) Acceptance criteria: 56.0%–68.0% (NF 1-May-2022)

4 IMPURITIES

Change to read:

4.1 Limit of Benzene

Diluent: 166 mL/L of Dimethyl sulfoxide in water

Standard stock solution: 1.75 mg/g of benzene in dimethyl sulfoxide

Standard solution A: Transfer 50 ± 1 mg of Carbomer 941 to a 20-mL headspace vial, and add 6 mL of Diluent to the vial. Weigh the vial. Using a syringe, add 10 μL of the Standard stock solution to the vial. Weigh the vial. Calculate the weight of the added Standard stock solution. Seal the vial with a Teon-lined rubber septum and aluminum crimp cap. Shake the vial for 1 h.

Standard solution B: Transfer 50 ± 1 mg of Carbomer 941 to a 20-mL headspace vial, and add 6 mL of Diluent to the vial. Weigh the vial. Using a syringe, add 20 μL of the Standard stock solution to the vial. Weigh the vial. Calculate the weight of the added Standard stock solution. Seal the vial with a Teon-lined rubber septum and aluminum crimp cap. Shake the vial for 1 h.

Standard solution C: Transfer 50 ± 1 mg of Carbomer 941 to a 20-mL headspace vial, and add 6 mL of Diluent to the vial. Weigh the vial. Using a syringe, add 50 μL of the Standard stock solution to the vial. Weigh the vial. Calculate the weight of the added Standard stock solution. Seal the vial with a Teon-lined rubber septum and aluminum crimp cap. Shake the vial for 1 h.

Sample solution: Transfer 50 ± 1 mg of Carbomer 941 to a 20-mL headspace vial, and add 6 mL of Diluent to the vial. Seal the vial with a Teon-lined rubber septum and aluminum crimp cap. Shake for 1 h.

4.1.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: GC, equipped with a headspace injector

Detector: Flame ionization

Column: 0.53-mm × 30-m fused silica; coated with 3.0-μm stationary phase G43

Temperatures

Injection port: 140°

Detector: 250°

Column: See Table 1.

Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature(min) |

40 | — | 40 | 10 |

40 | 30 | 240 | 5 |

Carrier gas: Helium

Flow rate: 5 mL/min (at a linear velocity of 35 cm/s programmed in constant pressure mode)

Injection volume: 1 mL (gaseous phase)

Injection type: Split, split ratio, 10:1

[Note—The following headspace conditions may be used: a vial pressure of 10 psi, a loop ll pressure (if equipped) of 7 psi, and a transfer line temperature of 105°.]

Vial temperature: The vials are maintained at a temperature of 80° for 45 min before headspace injection.

4.1.2 System suitability

Sample: Standard solution B

Suitability requirements

4.1.3 Analysis

Samples: Standard solution A, Standard solution B, Standard solution C, and Sample solution

The detector response factor (RF) of each Standard solution is determined by:

RF = (WSS × CSS )/(rS − rU)

WSS = weight of the Standard stock solution in each Standard solution

CSS = concentration of benzene in Standard stock solution (mg/g)

rS = peak area of benzene in each Standard solution

rU = peak area of benzene in the Sample solution

Average three RF to obtain RFavg . Calculate the percentage of benzene in the portion of Carbomer 941 taken:

Result = [(RFavg × )/WU ] × 100

RFavg = average of three RF

rU = benzene peak area of the Sample solution

WU = weight of Carbomer 941 in the Sample solution (mg)

(NF 1-May-2022)

Acceptance criteria: NMT 0.5% Add the following:

4.2 Limit of Acrylic Acid

Solution A: Methanol

Solution B: Dissolve 6.80 g of monobasic potassium phosphate in 300 mL of water, and dilute with water to 500 mL. Dilute 100 mL of this solution to 1 L, and adjust with phosphoric acid to a pH of 3.0 ± 0.1. Filter and degas.

Mobile phase: See Table 2.

Time (min) | Solution A (%) | Solution B (%) | Flow Rate (mL/min) |

0 | 5 | 95 | 1.0 |

8 | 5 | 95 | 1.0 |

9 | 10 | 90 | 1.5 |

19 | 10 | 90 | 1.5 |

20 | 5 | 95 | 1.0 |

25 | 5 | 95 | 1.0 |

Standard solution A: 2 μg/g of acrylic acid (w/w)

Standard solution B: 50 μg/g of acrylic acid (w/w)

Standard solution C: 100 μg/g of acrylic acid (w/w)

Sample solution: Transfer 100 mg of Carbomer 941 to a tared serum vial. Add water to obtain a total weight of 10 g of solution. Cap the vial and shake by mechanical means for 2 h. Add 2 drops of sodium hydroxide solution (50% w/v), and shake by hand for 15 s. Add 1.0 mL of calcium chloride solution (100 mg/mL), and shake until the gel collapses. Record the weight of all additions of water, sodium hydroxide, and calcium chloride. Centrifuge for 15 min, and use the clear supernatant.

4.2.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 200 nm

Column: 4.6-mm x 15-cm; 5-μm packing L1

Flow rate: See Table 2.

Injection volume: 10 μL

System suitability

Sample: Standard solution B

Suitability requirements

Relative standard deviation: NMT 5% from 3 injections

4.2.2 Analysis

Samples: Standard solution A, Standard solution B, Standard solution C, and Sample solution

Analyze each Standard solution, and plot the peak area versus concentration. Plot should be linear with an r2 equal or greater than 0.9990. The slope of the calibration curve (area/ppm acrylic acid) is the response factor. Calculate the percentage of free acrylic acid in the portion of polymer taken:

Result (wt%) = (rU /RF)/CU × F × 100

rU = peak response of acrylic acid from the Sample solution

RF = response factor [peak area/(μg/g)]

CU = concentration of Carbomer 941 in the Sample solution (mg/g)

F = unit conversion factor, 10–3 (mg/μg)

Acceptance criteria: NMT 0.25% (NF 1-May-2022)

4.3 Viscosity—Rotational Methods 〈912〉

Sample: 2.50 g of Carbomer 941, (NF 1-May-2022) dried under vacuum at 80° for 1 h

Titrimetric system

(See Titrimetry 〈541〉.)

Mode: Direct titration

Electrode: Calomel–glass or silver/silver chloride (NF 1-May-2022)

Titrant: 180 mg/mL of sodium hydroxide

Endpoint detection: pH

Analysis: Carefully add the Sample to 500 mL of water in an 800-mL (NF 1-May-2022) beaker,1 (NF 1-May-2022) while stirring continuously at 1000 ± 10 rpm, with the stirrer shaft set to the side of the beaker at an angle of 60° and with the propeller positioned near the bottom of the beaker. Allow 45–90 s for addition of the Sample at a uniform rate, being sure that loose aggregates of powder are broken up, and continue stirring at 1000 ± 10 rpm for 15 min. [Note—Proper dispersion of the carbomer resin is imperative for accurate viscosity readings.] (NF 1-May-2022) Remove the stirrer, and place the beaker containing the dispersion in a 25 ± 0.1° water bath for 30 min. Insert the stirrer to a depth necessary to ensure that air is not drawn into the dispersion, and while stirring at 300 ± 25 (NF 1-May-2022) rpm, titrate with Titrant to a pH of 7.3–7.8. (NF 1-May-2022) Stir for 2–3 min until neutralization is complete. [Note—After neutralization, care must be taken to avoid excessively high shearing, because aggressive mixing will break the polymer chains and reduce the viscosity reading.] (NF 1-May-2022) Then determine the nal pH.2 (NF 1-May-2022) If the pH is below (NF 1-May-2022) 7.3, raise it with additional Titrant. (NF 1-May-2022) If it is more than 7.8, discard the mucilage, and prepare another, using a smaller amount of Titrant (NF 1-May-2022) for titration. Return the beaker containing the (NF 1-May-2022) neutralized mucilage to the 25 ± 0.1° (NF 1-May-2022) water bath for 1 h. (NF 1-May2022) Perform the viscosity determination without delay to avoid slight viscosity changes that occur 75 min after neutralization. Equip a suitable rotational viscometer with a spindle having a disk about 2.a1 cm in diameter and 0.2 cm high, attached to a shaft 0.3 cm in diameter, the distance from the top of the disk to the lower tip of the shaft being 2.7 cm.3 The spindle rotates at 20 rpm at an immersion depth of 4.9 cm. Follow the instrument manufacturer's directions to measure the apparent viscosity.

Acceptance criteria: 4,000–11,000 mPa · s

5 ADDITIONAL REQUIREMENTS

Change to read:

Packaging and Storage: Product is hygroscopic. Preserve in tight containers away from direct sources of moisture. (NF 1-May-2022)

Labeling: Label it to indicate that it is not intended for internal use. A carbomer homopolymer manufactured using benzene and complying with the unique requirements of this monograph will be ocially titled Carbomer 941 and will not be referred to as Carbomer Homopolymer.

Add the following:

USP Reference Standards 〈11〉

USP Carbomer Homopolymer RS (NF 1-May-2022)

1 A beaker size of 600–1000 mL is ideal for this method. However, the minimum inside diameter of the beaker should be 83 mm.

2 If formation of a very viscous gel is observed at a pH of 7.3–7.8, the tested material conforms to Identication C.

3 Available as an RV5 spindle from Brookeld, or the equivalent.