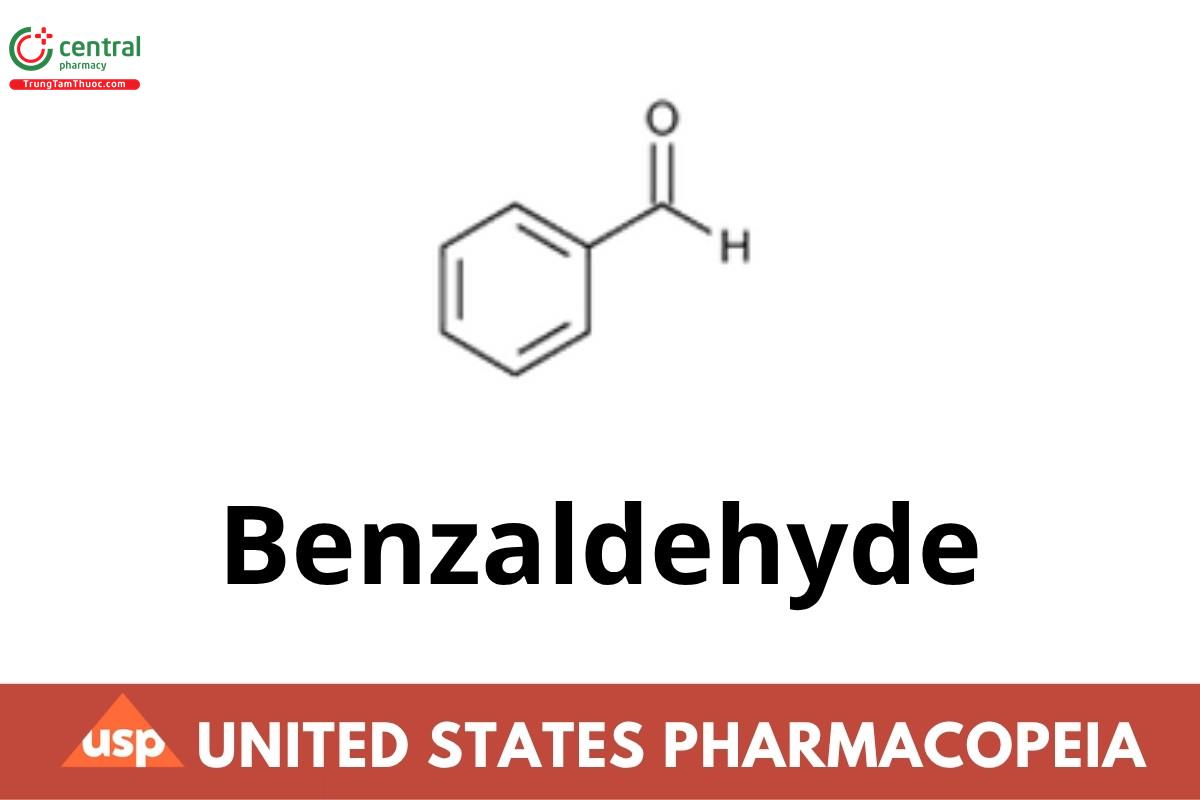

Benzaldehyde

If you find any inaccurate information, please let us know by providing your feedback here

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

1 DEFINITION

Benzaldehyde contains NLT 98.0% and NMT 102.0% of benzaldehyde (C7H6O).

2 IDENTIFICATION

Change to read:

A. SPECTROSCOPIC IDENTIFICATION TESTS 〈197〉 , Infrared Spectroscopy : 197F (CN 1-M -2020)

3 ASSAY

PROCEDURE

Solution A: Acetonitrile and glacial acetic acid (1000:1, v/v) Solution B: Glacial acetic acid and water (1:1000, v/v)

Mobile phase: See Table 1.

Table 1

| Time (min) | Solution A (%) | Solution B (%) |

| 0 | 18 | 82 |

| 20 | 60 | 40 |

| 30 | 60 | 40 |

System suitability solution: 0.1 mg/mL of USP Benzoic Acid RS and 0.06 mg/mL of USP Methylparaben RS in acetonitrile Standard solution: 0.15 mg/mL of USP Benzaldehyde RS in acetonitrile

Sample solution: 0.15 mg/mL of Benzaldehyde in acetonitrile

3.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.) Mode: LC

Detector: UV 235 nm

Column: 4.6-mm × 25-cm; 5-µm packing L1 Flow rate: 1.2 mL/min

Injection volume: 10 µL

3.2 System suitability

Samples: System suitability solution and Standard solution

Suitability requirements

Resolution: NLT 2.0 between benzoic acid and methylparaben, System suitability solution Tailing factor: NMT 2.0 for benzoic acid and methylparaben, System suitability solution Relative standard deviation: NMT 2.0% for benzaldehyde, Standard solution

3.3 Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of benzaldehyde (C7H6O) in the portion of Benzaldehyde taken:

Result = (ru/rs) × (Cs/Cu) × 100

ru = peak response of benzaldehyde from the Sample solution

rs = peak response of benzaldehyde from the Standard solution

Cs = concentration of USP Benzaldehyde RS in the Standard solution (mg/mL)

Cu = concentration of Benzaldehyde in the Sample solution (mg/mL)

Acceptance criteria: 98.0%–102.0%

4 IMPURITIES

4.1 LIMIT OF HYDROCYANIC ACID

Sample solution: Shake 0.5 mL of Benzaldehyde with 5 mL of water, add 0.5 mL of 1 N sodium hydroxide and 0.1 mL of ferrous sulfate TS, and warm the mixture gently.

Acceptance criteria: Upon the addition of a slight excess of hydrochloric acid, no greenish-blue color or blue precipitate is produced within 15 min.

4.2 LIMIT OF NITROBENZENE

Sample solution: Dissolve 1 mL of Benzaldehyde in 20 mL of alcohol, and mix with 10 mL of water.

Analysis: Add 1-g portions of zinc and 1-mL portions of 2 N sulfuric acid, as needed, to maintain a brisk evolution of hydrogen for 1 h. Filter, evaporate the liquid to 20 mL, and boil 10 mL of the concentrated liquid with 1 drop of potassium dichromate TS.

Acceptance criteria: No purplish color is produced.

4.3 CHLORINATED COMPOUNDS

Analysis: Wind a strip of 20-mesh copper gauze 1.5 cm wide and 5 cm long around the end of a copper wire. Heat the gauze in the nonluminous flame of a Bunsen burner until it glows without coloring the flame green. Permit the gauze to cool, and heat several times until a thick coat of oxide has formed. With a medicine dropper, apply 2 drops of Benzaldehyde to the cooled gauze, ignite, and permit it to burn freely in the air. Again cool the gauze, add 2 more drops of Benzaldehyde, and burn as before. Repeat this process until a total of 6 drops have been added and ignited. Then hold the gauze in the outer edge of the Bunsen flame, adjusted to a height of 4 cm.

Acceptance criteria: Not even a transient green color is imparted to the flame.

4.4 LIMIT OF ETHYLBENZENE, CYCLOHEXYLMETHANOL, BENZYL ALCOHOL, AND BENZOIC ACID

Sample solution: Neat Benzaldehyde

Standard solution: 0.1% of USP Ethylbenzene RS, 0.1% of USP Cyclohexylmethanol RS, 0.2% of USP Benzoic Acid RS, and 0.2% of USP Benzaldehyde RS in USP Benzyl Alcohol RS

4.4.1 Chromatographic system

(See Chromatography 〈621〉, System Suitability.) Mode: GC

Detector: Flame ionization

Column: 0.32-mm × 30-m fused silica capillary, coated with a 0.5-µm layer of phase G16 Temperatures

Detector: 310°

Injection port: 200° Column: See Table 2.

Table 2

| Initial Temperature (°) | Temperature Ramp (°/min) | Final Temperature (°) | Hold Time at Final Temperature (min) |

| 50 | 5 | 220 | 35 |

Carrier gas: Helium Flow rate: 1.2 mL/min Injection volume: 0.1 µL

Injection type: Splitless injection

4.5 System suitability

Sample: Standard solution

[NOTE—For relative retention times, see Table 3.]

Table 3

| Component | Relative Retention Time |

| Ethylbenzene | 0.45 |

| Benzaldehyde | 1.00 |

| Cyclohexylmethanol | 1.03 |

| Benzyl alcohol | 1.45 |

| Benzoic acid | 2.04 |

System suitability requirements

Resolution: NLT 3.0 between benzaldehyde and cyclohexylmethanol

4.5.1 Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of each impurity in the portion of Benzaldehyde taken:

Result = (ru/rT) × 100

ru = peak response of each impurity from the Sample solution

rT = sum of all the peak responses from the Sample solution

4.5.2 Acceptance criteria

Each individual impurity: NMT 1.0%

Total impurities: NMT 2.0%

5 SPECIFIC TESTS

WATER DETERMINATION, Method I 〈921〉: NMT 1.5%

6 ADDITIONAL REQUIREMENTS

6.1 PACKAGING AND STORAGE

Preserve in well-filled, tight, light-resistant containers. Store at room temperature, and avoid exposure to excessive heat.

6.2 USP REFERENCE STANDARDS 〈11〉

USP Benzaldehyde RS USP Benzoic Acid RS USP Benzyl Alcohol RS

USP Cyclohexylmethanol RS USP Ethylbenzene RS

USP Methylparaben RS