Amino Methacrylate Copolymer

If you find any inaccurate information, please let us know by providing your feedback here

Tóm tắt nội dung

This article is compiled based on the United States Pharmacopeia (USP) – 2025 Edition

Issued and maintained by the United States Pharmacopeial Convention (USP)

DOWNLOAD PDF HERE

.jpg)

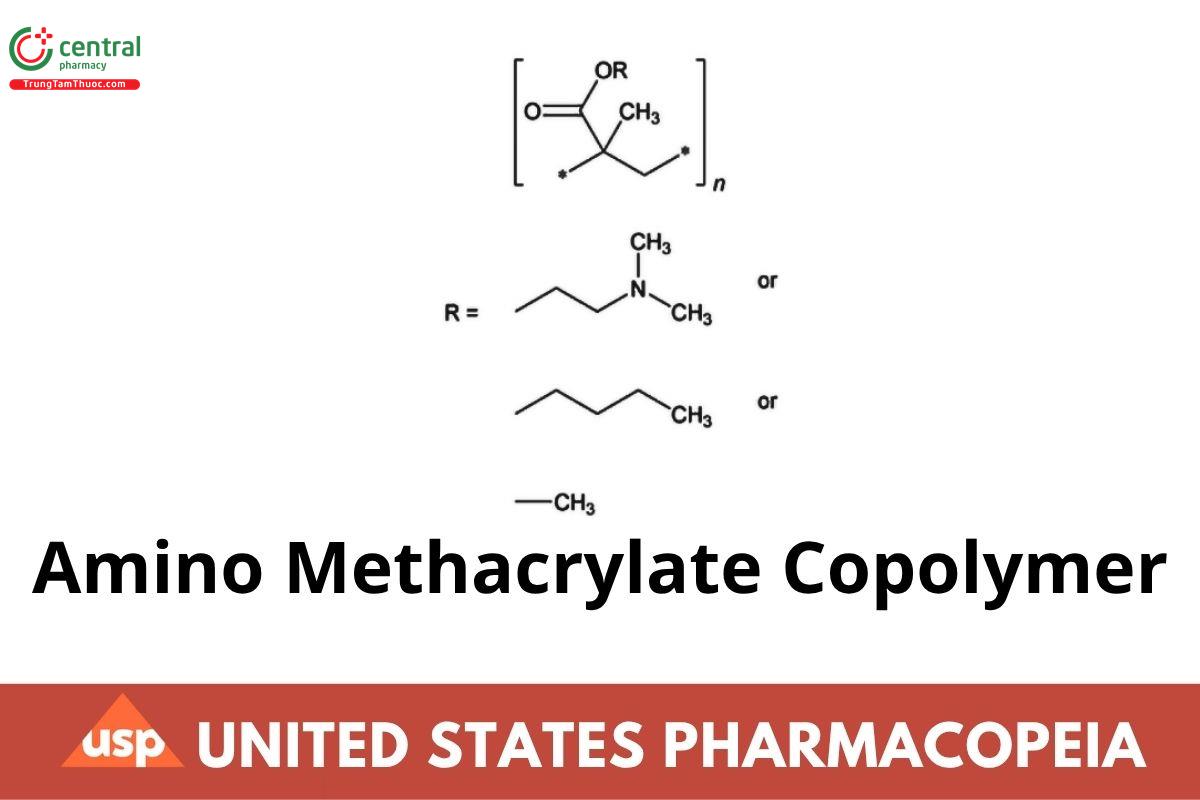

Ratio: CH2CH2N(CH3)2:C4H9:CH3= 2:1:1

Poly((2-dimethylaminoethyl)methacrylate, butyl methacrylate, methyl methacrylate) (2:1:1);

N,N-Dimethylaminoethyl methacrylate–butyl methacrylate–methyl methacrylate copolymer (2:1:1)

CAS RN®: 24938-16-7.

1 DEFINITION

Amino Methacrylate Copolymer is a polymerized copolymer of (2-dimethylaminoethyl) methacrylate, butyl methacrylate, and methyl methacrylate. It contains NLT 20.8% and NMT 25.5% of dimethylaminoethyl groups (C H N), calculated on the dried basis.

2 IDENTIFICATION

Change to read:

A. Spectroscopic Identification Tests 〈197〉, Infrared Spectroscopy: 197K (CN 1-May-2020)

B.

Sample solution: 1 mL of the Sample solution in the test for Viscosity

Analysis: Pour the Sample solution onto a glass plate, and allow the solvent to evaporate.

Acceptance criteria: A clear, colorless

lm results.

3 ASSAY

Procedure

Sample: 200 mg

Blank: 4 mL of water and 96 mL of glacial acetic acid

Titrimetric system

(See Titrimetry 〈541〉.)

Mode: Direct titration

Titrant: 0.1 N perchloric acid VS

Endpoint detection: Potentiometric

Analysis: Dissolve the Sample in a mixture of 4 mL of water and 96 mL of glacial acetic acid. Titrate with the Titrant to a potentiometric endpoint. Perform a blank determination.

Calculate the percentage of dimethylaminoethyl groups (C4H10N) in the portion of the sample taken:

Result ={[(VS− VB) × N × F]/W} × 100

VS= Titrant volume consumed by the Sample (mL)

VB= Titrant volume consumed by the Blank (mL)

N = actual normality of the Titrant (mEq/mL)

F = equivalency factor, 72.1 mg/mEq

W = Sample weight (mg)

Acceptance criteria: 20.8%–25.5% on the dried basis

4 IMPURITIES

Residue on Ignition 〈281〉: NMT 0.1%

Limit of Butyl Methacrylate and Methyl Methacrylate

Buffer: 8.9 g/L of anhydrous dibasic sodium phosphate and 8.5 g/L of monobasic potassium phosphate. Adjust with phosphoric acid to a pH of 2.0. This is pH 2.0 phosphate buffer (0.0625 M).

Mobile phase: Methanol and Buffer (55:45)

Diluent: Acetonitrile and Buffer (40:60)

Standard solution: Dissolve 20 mg of butyl methacrylate and 10 mg of methyl methacrylate in 3 mL of n-butanol. Dilute with Diluent to 10 mL.

Dilute 1.0 mL of this solution with Diluent to 250.0 mL, and mix. This solution contains about 8 μg/mL of butyl methylcrylate and 4 μg/mL of methyl methacrylate.

Sample solution: 20 mg/mL of Amino Methacrylate Copolymer in Diluent

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 205 nm

Column: 4.6-mm × 12-cm; packing L1

Flow rate: 2 mL/min

Injection volume: 50 μL

System suitability

Sample: Standard solution

Suitability requirements

Resolution: NLT 10 between butyl methacrylate and methyl methacrylate

Relative standard deviation: NMT 3.0%

Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of each monomer in the portion of Amino Methacrylate Copolymer taken:

Result = (rU/rS) × (CS/CU) × F × 100

rU= peak response of each monomer (butyl methacrylate or methyl methacrylate) from the Sample solution

rS= peak response of each monomer (butyl methacrylate or methyl methacrylate) from the Standard solution

CS= concentration of each monomer (butyl methacrylate or methyl methacrylate) in the Standard solution (μg/mL)

CU= concentration of Amino Methacrylate Copolymer in the Sample solution (mg/mL)

F = conversion factor, 10−3 mg/μg

Acceptance criteria: NMT 0.1% for each monomer

Limit of 2-Dimethylaminoethyl Methacrylate

Buffer: 3.4 g/L of monobasic potassium phosphate. This is the monobasic potassium phosphate solution (0.025 M).

Mobile phase: Tetrahydrofuran and Buffer (75:25)

Standard solution: 8 μg/mL of 2-dimethylaminoethyl methacrylate in tetrahydrofuran

Sample solution: 20 mg/mL of Amino Methacrylate Copolymer in tetrahydrofuran

Chromatographic system

(See Chromatography 〈621〉, System Suitability.)

Mode: LC

Detector: UV 215 nm

Column: 4.6-mm × 12-cm; packing L8

Flow rate: 2 mL/min

Injection volume: 50 μL

System suitability

Sample: Standard solution

Suitability requirements

Relative standard deviation: NMT 2.0%

Analysis

Samples: Standard solution and Sample solution

Calculate the percentage of 2-dimethylaminoethyl methacrylate in the portion of Amino Methacrylate Copolymer taken:

Result = (rU/rS) × (CS/CU) × F × 100

rU= peak response of 2-dimethylaminoethyl methacrylate from the Sample solution

rS= peak response of 2-dimethylaminoethyl methacrylate from the Standard solution

CS= concentration of 2-dimethylaminoethyl methacrylate in the Standard solution (μg/mL)

CU = concentration of Amino Methacrylate Copolymer in the Sample solution (mg/mL)

F = conversion factor, 10−3 mg/μg

Acceptance criteria: NMT 0.1%

5 SPECIFIC TESTS

5.1 Viscosity—Rotational Methods 〈912〉

Sample solution: Dissolve 12.5 g in a mixture of 35.0 g of acetone and 52.5 g of isopropyl alcohol. [Note—Reserve a portion of this solution for the Color of Solution test.]

Analysis: Equip a suitable rotational viscometer with an adapter comprising a cylindrical spindle rotating within an accurately machined chamber (or tube).1Pipet the Sample solution in the speci

ed volume, which is recommended by the instrument manufacturer, into the chamber (or tube), and ensure that the temperature of the test specimen is at 20 ± 0.1°. The cylindrical spindle rotates at the value of rpm, which corresponds to a rate of shear of approximately 37 s−1.2

Measure the apparent viscosity following the instrument manufacturer's directions.

Acceptance criteria: Viscosity, 3–6 mPa · s

5.2 Color of Solution

Sample solution: Use the Sample solution prepared in the test for Viscosity.

Instrumental conditions

(See Ultraviolet-Visible Spectroscopy 〈857〉.)

Mode: Vis

Analytical wavelength: 420 nm

Cell: 1 cm

Analysis: Determine the absorbance of the Sample, using water as the blank.

Acceptance criteria: NMT 0.300

5.3 Loss on Drying 〈731〉

Analysis: Dry a sample at 110° for 3 h.

Acceptance criteria: NMT 2.0%

6 ADDITIONAL REQUIREMENTS

Packaging and Storage: Preserve in tight containers, and store at a temperature below 30°.

USP Reference Standards 〈11〉

USP Amino Methacrylate Copolymer RS

1 A commercial device is available from Brookfield as an ultra-low (UL) viscosity adapter. The adapter comprises a 0.4-cm diameter shaft, an accurately machined chamber (or tube) with an internal diameter of 2.8 cm and a depth of 13.5 cm, and a cylindrical spindle 2.5 cm in diameter and 9.1 cm in height.

2 For the Brookfield UL adapter, the cylindrical spindle rotates at 30 rpm, which corresponds to a rate of shear of approximately 37 s−1